|

|

© 2012 by RULMECA Corporation |

|

Buzzi Unicem USA Expands Usage of Rulmeca Motorized Pulleys

|

|

Four Buzzi Unicem USA cement plants upgrade conveyor drives: Pryor, OK; Festus, MO; Greencastle, IN; and Stockertown, PA. Read complete story published by World Cement in Bulk Materials Handling Review 2011. |

|||

Greencastle, IN Syn Gyp:

JBM Incorporated designed, fabricated, and installed new synthetic gypsum

receiving systems at Buzzi Unicem USA's Greencastle, IN (pictured here) and Festus, MO plants which included model 220H Motorized Pulleys. This followed a raw material hopper collector conveyor upgrade with model 320M at the Pryor, OK cement plant. Greencastle, IN Syn Gyp:

JBM Incorporated designed, fabricated, and installed new synthetic gypsum

receiving systems at Buzzi Unicem USA's Greencastle, IN (pictured here) and Festus, MO plants which included model 220H Motorized Pulleys. This followed a raw material hopper collector conveyor upgrade with model 320M at the Pryor, OK cement plant.

|

|||

Pryor, OK Reclaim Tunnel Conveyor:

Having monitored the Motorized Pulley performance on the collector conveyors, Buzzi personnel decided to replace an underpowered 75 HP exposed drive on a reclaim tunnel conveyor problem with two 50 HP model 630H Rulmeca Motorized Pulleys. Pryor, OK Reclaim Tunnel Conveyor:

Having monitored the Motorized Pulley performance on the collector conveyors, Buzzi personnel decided to replace an underpowered 75 HP exposed drive on a reclaim tunnel conveyor problem with two 50 HP model 630H Rulmeca Motorized Pulleys.

|

|||

50 HP Dual Drive Head Pulley:

Note foundation for original 75 HP exposed motor and gearbox in foreground. New 24" diameter 50 HP Motorized Pulley is completely enclosed within chute. Only terminal box is visible. Plant personnel were surprised that both Motorized Pulleys, weighing just 1,850 lbs each, were installed in the head and tail positions in just one shift. 50 HP Dual Drive Head Pulley:

Note foundation for original 75 HP exposed motor and gearbox in foreground. New 24" diameter 50 HP Motorized Pulley is completely enclosed within chute. Only terminal box is visible. Plant personnel were surprised that both Motorized Pulleys, weighing just 1,850 lbs each, were installed in the head and tail positions in just one shift.

|

|||

50 HP Dual Drive Tail Pulley:

Model 630H Motorized Pulley is located in the reclaim tunnel, 550 feet from and 138 feet below the 630H in the head pulley position. The two Motorized Pulleys are controlled and synchronized through the use of flux vector variable frequency drives. Initial testing, performed before the VFDs were installed, verified that the dual drive system would start an overloaded belt. 50 HP Dual Drive Tail Pulley:

Model 630H Motorized Pulley is located in the reclaim tunnel, 550 feet from and 138 feet below the 630H in the head pulley position. The two Motorized Pulleys are controlled and synchronized through the use of flux vector variable frequency drives. Initial testing, performed before the VFDs were installed, verified that the dual drive system would start an overloaded belt.

|

|||

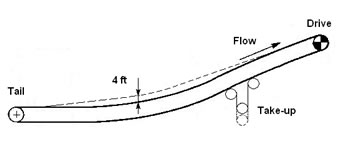

Four Foot Belt Empty Bounce Eliminated:

A significant benefit of the dual drive system is the elimination of empty belt bounce at start-up. The system no longer causes belt and structural damage due to belt bounce because effective belt tension is spread evenly between the head and tail drive pulleys. Furthermore, the dual drive system provides 360 degrees of belt wrap instead of 180 degrees. Calculations showed that slack side tension could be reduced by 2,000 lbs, extending belt life siginificantly. Instead of replacing the 30 inch wide 3 ply belt with a 4 ply belt, as originally planned, the dual drive system enabled the plant to continue using the 3 ply belt, even with 33% more power. This means that the new Motorized Pulley dual drive system solved both the overloaded belt start-up problem and the unloaded belt start-up problem. Four Foot Belt Empty Bounce Eliminated:

A significant benefit of the dual drive system is the elimination of empty belt bounce at start-up. The system no longer causes belt and structural damage due to belt bounce because effective belt tension is spread evenly between the head and tail drive pulleys. Furthermore, the dual drive system provides 360 degrees of belt wrap instead of 180 degrees. Calculations showed that slack side tension could be reduced by 2,000 lbs, extending belt life siginificantly. Instead of replacing the 30 inch wide 3 ply belt with a 4 ply belt, as originally planned, the dual drive system enabled the plant to continue using the 3 ply belt, even with 33% more power. This means that the new Motorized Pulley dual drive system solved both the overloaded belt start-up problem and the unloaded belt start-up problem.

|

|||

Feeder Drive with Wide Speed Range:

High Rock W eigh feeder has 30 inch wide belt with 4 inch sidewalls and is driven by 16 inch diamater 5.5 HP Motorized Pulley at 0.8 to 80 fpm. Since Motorized Pulleys cool their motors by transferring heat through the pulley shell into the conveyor belt, it was essential to verify that adequate cooling was available though the wide frequency spectrum of 1 Hz to 100 Hz. This allowed the plant to achieve a material throughput of less than 1 tph to more than 100 tpm. Feeder Drive with Wide Speed Range:

High Rock W eigh feeder has 30 inch wide belt with 4 inch sidewalls and is driven by 16 inch diamater 5.5 HP Motorized Pulley at 0.8 to 80 fpm. Since Motorized Pulleys cool their motors by transferring heat through the pulley shell into the conveyor belt, it was essential to verify that adequate cooling was available though the wide frequency spectrum of 1 Hz to 100 Hz. This allowed the plant to achieve a material throughput of less than 1 tph to more than 100 tpm.

|

|||

|

|