|

|

© 2012 by RULMECA Corporation |

|

Bulk Solids Handling Journal Features Article on Rulmeca Motorized Pulleys

|

|

Bulk Solids Handling Journal Issue 03/2012 features Rulmeca Motorized Pulleys at five major bulk transfer terminals in US and UK including: Duluth Dock, Escanaba Ore Terminal, Cargill Deicing Barge Terminal, Clydeport Hunterston Terminal, and Allouez Dock. Click here for full story. |

|||

Duluth Dock:

Built in 1918 as a gravity feed dock, the Duluth Dock is the most recent North American ship loading facility to upgrade with Rulmeca Motorized Pulleys. Two 180 HP Rulmeca Motorized Pulleys were installed at opposite ends of the reversing shuttle belt above the huge ship loader surge bins. Each of the Motorized Pulleys operates independent of the other. The east drive is energized to move material eastward and the west drive is energized to move material westward. An enclosed cab is positioned at each end of the shuttle conveyor to provide a clear line of sight to the operator. For example, when material is transferred west, operator sits in west cab to control shuttle travel and location of articulating boom. Duluth Dock:

Built in 1918 as a gravity feed dock, the Duluth Dock is the most recent North American ship loading facility to upgrade with Rulmeca Motorized Pulleys. Two 180 HP Rulmeca Motorized Pulleys were installed at opposite ends of the reversing shuttle belt above the huge ship loader surge bins. Each of the Motorized Pulleys operates independent of the other. The east drive is energized to move material eastward and the west drive is energized to move material westward. An enclosed cab is positioned at each end of the shuttle conveyor to provide a clear line of sight to the operator. For example, when material is transferred west, operator sits in west cab to control shuttle travel and location of articulating boom.

|

|||

Allouez Dock:

Located in the greater Duluth area, the Allouez Dock, owned and operated by BNSF Railway, installed three Rulmeca Motorized Pulleys to upgrade conveyor drives on a forty year old bucket wheel reclaimer in 2004 and nine more since then. Gary Kucharyski,

Allouez Dock Maintenance Supervisor, said, “The use of two Motorized Pulleys on each of our three reclaimer discharge conveyors has enabled us to reduce slack side tension and increase the service life of our belts. We are pleased not only with the reliability of our Rulmeca Motorized Pulleys but also with the extended belt life they have yielded.”

Allouez Dock:

Located in the greater Duluth area, the Allouez Dock, owned and operated by BNSF Railway, installed three Rulmeca Motorized Pulleys to upgrade conveyor drives on a forty year old bucket wheel reclaimer in 2004 and nine more since then. Gary Kucharyski,

Allouez Dock Maintenance Supervisor, said, “The use of two Motorized Pulleys on each of our three reclaimer discharge conveyors has enabled us to reduce slack side tension and increase the service life of our belts. We are pleased not only with the reliability of our Rulmeca Motorized Pulleys but also with the extended belt life they have yielded.”

|

|||

Allouez Dock Dual Drive:

The dual drive system is “nested” beneath the discharge conveyor. The serpentine arrangement yielded 420 degrees of belt wrap, significantly more than the original 180 degrees. Calculations showed that the additional belt wrap reduced slack side tension to prevent belt slippage and/or sag, T2, by 29%. This drop in T2 resulted in a reduction of 13% in T1, total belt tension. Allouez Dock Dual Drive:

The dual drive system is “nested” beneath the discharge conveyor. The serpentine arrangement yielded 420 degrees of belt wrap, significantly more than the original 180 degrees. Calculations showed that the additional belt wrap reduced slack side tension to prevent belt slippage and/or sag, T2, by 29%. This drop in T2 resulted in a reduction of 13% in T1, total belt tension.

|

|||

Cargill Deicing Salt Mine & Barge Terminal:

1,200 miles from Duluth in the swampy region of Louisiana, Cargill Deicing operates a salt mine and barge loading terminal. The deep mine has battled the effects of corrosion and abrasion since the mine shaft was first sunk into the huge salt dome in 1862. However, it was not until Everett McBride first tried Rulmeca Motorized Pulleys in the barge loading system in 2004 that the company began seriously converting their exposed conveyor drive systems to internally-powered conveyor drive pulleys. Cargill Deicing Salt Mine & Barge Terminal:

1,200 miles from Duluth in the swampy region of Louisiana, Cargill Deicing operates a salt mine and barge loading terminal. The deep mine has battled the effects of corrosion and abrasion since the mine shaft was first sunk into the huge salt dome in 1862. However, it was not until Everett McBride first tried Rulmeca Motorized Pulleys in the barge loading system in 2004 that the company began seriously converting their exposed conveyor drive systems to internally-powered conveyor drive pulleys.

|

|||

Cargill Deicing (After):

Now the mine enjoys higher system reliability and lower maintenance expense because the Rulmeca Pulleys enclose all drive components within an oil filled hermetically-sealed pulley shell. Rather than struggling to protect moving components, Cargill “hides” them out of harm’s way. Cargill Deicing (After):

Now the mine enjoys higher system reliability and lower maintenance expense because the Rulmeca Pulleys enclose all drive components within an oil filled hermetically-sealed pulley shell. Rather than struggling to protect moving components, Cargill “hides” them out of harm’s way.

|

|||

Cargill Deicing (Before):

Operations and maintenance personnel use stainless steel, special paint, and wooden structures to combat corrosion due to salt accumulation in the humid Louisiana marshlands. As shown in the photo taken before the exposed drive system was removed, salt accumulation on metal surfaces caused corrsion problems and plugged motor cooling fins and fans.

Cargill Deicing (Before):

Operations and maintenance personnel use stainless steel, special paint, and wooden structures to combat corrosion due to salt accumulation in the humid Louisiana marshlands. As shown in the photo taken before the exposed drive system was removed, salt accumulation on metal surfaces caused corrsion problems and plugged motor cooling fins and fans.

|

|||

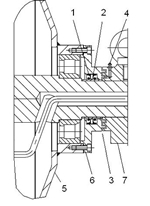

Motorized Pulley Labyrinth Seals:

Special features incorporated into the Cargill Motorized Pulleys include inorganic zinc rich primer, 12 mils of Carboline Carbomastic CM15FC paint, regreasable labyrinth seals, and stainless steel shafts. The paint system protects steel and cast iron surfaces while the labyrinth seals provide a grease barrier to protect all double lip shaft seals. In addition, Class H motors and synthetic oil protect the drive system from the heat of the Louisiana marshland climate.

Motorized Pulley Labyrinth Seals:

Special features incorporated into the Cargill Motorized Pulleys include inorganic zinc rich primer, 12 mils of Carboline Carbomastic CM15FC paint, regreasable labyrinth seals, and stainless steel shafts. The paint system protects steel and cast iron surfaces while the labyrinth seals provide a grease barrier to protect all double lip shaft seals. In addition, Class H motors and synthetic oil protect the drive system from the heat of the Louisiana marshland climate.

|

|||

|

|