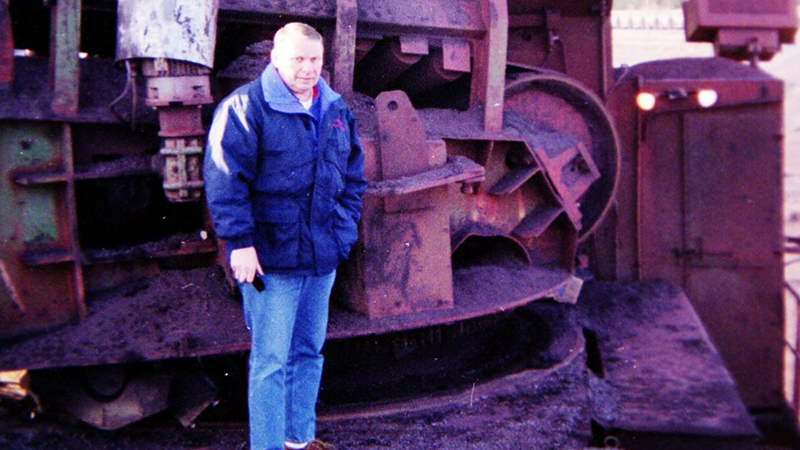

Rulmeca has many years of experience in supplying Motorized Pulleys to drive conveyors from the tail position, as shown in this vintage photo of a huge German mobile crushing machine. This blog describes a variety of successful “tail drive” applications, spanning more than 30 years. Inclined bulk handling conveyors are ideally driven from the head position. However, technical reasons (e.g. weight or space limitations) sometimes require that conveyors be driven from the tail. Rulmeca Motorized Pulleys facilitate locating the drive at the tail because of their light weight and small size, as shown in this blog post.

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

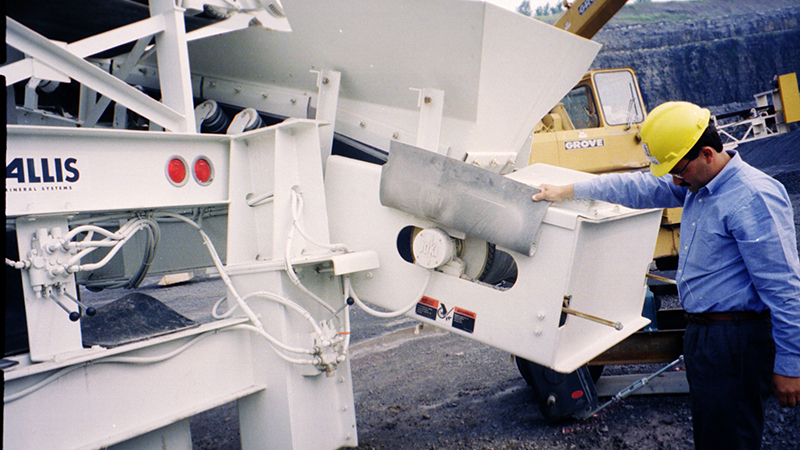

Manufactured in 1983, this 1,200 tph crawler-mounted primary crusher features a 24.8” diameter tail-mounted Rulmeca Motorized Pulley, which provides 75 HP to drive the 48” wide belt conveyor at 600 fpm on the 150’ long cantilevered discharge structure. Note that all electrical terminations are made in junction box attached to end of pulley shaft. Note also lifting lug attached to mounting bracket to facilitate pulley installation and change-out.

Truck and Shovel Limestone Quarry (Germany) – Crawler-mounted primary crusher links trucks and shovels at 1,000 TPH with traveling bridge conveyor and overland conveyor system at a cement company’s limestone quarry. The 140’ long 54” wide discharge conveyor (shown in “lowered position”) elevates to +14º and is driven by a tail-mounted 31.5” diameter 50 HP Motorized Pulley at 600 fpm. Photo was taken in 1993 when Rulmeca Motorized Pulleys were installed.

Continuous Open Pit Lignite Mine (Greece) – Since 1972 a 35’ diameter bucket wheel excavator has been feeding overburden to this discharge belt at a rate of 3,000 TPH. A 150 HP 31.5” diameter Rulmeca Motorized Pulley drives the 72” wide belt at 960 fpm. Note that Motorized Pulley is mounted in a mechanical belt take-up. Power cord festoon loop allows free movement of pulley to front and rear. First Motorized Pulleys were replaced after nearly 30 years of service.

Granite Quarry (USA) – Built in 2003, this mobile recirculating crushing and screening rig uses a tail-mounted 15 HP 15.75” diameter Motorized Pulley to drive the 36” wide 300 TPH 58’ long screen feed conveyor. Note that use of slender “Telescoping” mechanical belt take-up allows compact and lightweight structure. This plant

adheres to the maximum US highway clearance requirements of 12’-0” wide by 13’-6” high. Technical Precaution: When mounting a motorized pulley in a screw take-up always make sure that pulley centerline is perpendicular to belt centerline to avoid overstressing internal bearings.

Ship Loading Terminal (USA) – Crawler-mounted bucket wheel reclaimer handles taconite pellets at 5,000 TPH on 72” wide boom and tail belts at this facility. Terminal operator replaced both original conveyor drives with 40” diameter Rulmeca Motorized Pulleys in 1980 after 13 years of service. Photo shows tail-mounted 200 HP drive pulley for discharge conveyor.

Marl Pit at Cement Plant (USA) – Manufacturer delivered this crawler-mounted bucket wheel reclaimer in 2002 to excavate marl from a pit adjacent to the producer’s cement plant in South Carolina. It uses tail-mounted 31.5” diameter 100 HP Motorized Pulleys to drive the 54” wide boom and tail conveyor belts at 600 fpm. Externally mounted brakes prevent material from “rolling backwards” when conveyors are stopped because both conveyors can articulate to a 16º maximum inclination.

Trap Rock Quarry (USA) – This 850 TPH recirculating crushing and screening plant was built in 1994. The tail-mounted 15.75” diameter 15 HP Motorized Pulley drives the 36” wide screen feed belt, in tandem with an identical head-mounted drive, at 384 fpm. Motorized Pulleys enabled designers to adhere to the 12’ maximum allowable US highway clearance width. Tail drive is mounted in a “Sliding Pedestal” mechanical belt take-up and features a “festooned” power cable to accommodate pulley movement as belt stretches. Technical Precaution: When mounting a motorized pulley in a screw take-up always make sure that pulley centerline is perpendicular to belt centerline to avoid overstressing internal bearings.