When driving a conveyor drive motor with a variable frequency drive (VFD) it is essential that the operator/designer be aware of all required powers and all available powers at all relevant rates.

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

Rate is the quantity of something measured against something else. Material handling rate is defined in TPH in bulk handling. Conveyor belt speed is defined in FPM. Electric motor power is defined in HP at a specified power supply. Electrical power supply is defined in volts, number of phases, and frequency. It is important to note that if power supply frequency is changed from the supply rate to another rate, available electric motor power will be reduced.

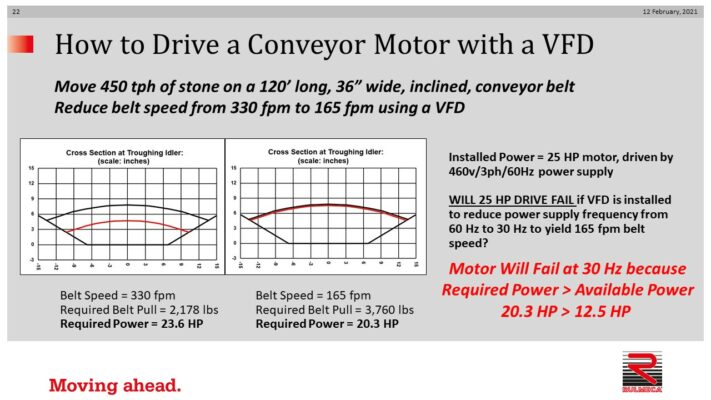

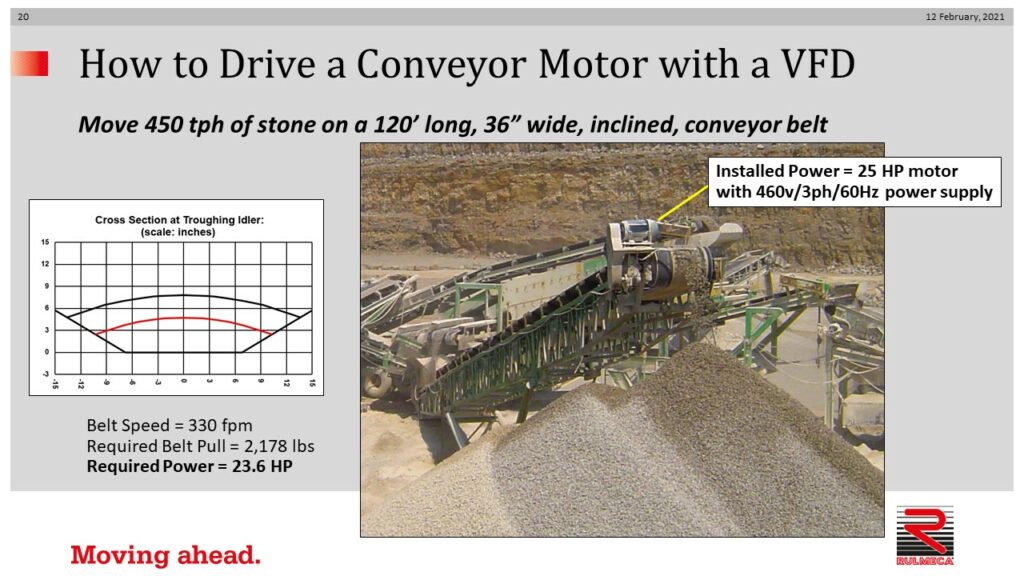

This belt conveyor is 120 feet (ft) long and 36 inches (in) wide and was originally designed to move 450 tons per hour (TPH) of stone at 330 feet per minute (FPM).

The diagram shows that 450 TPH of stone will fit within the trough of a 36 in wide conveyor belt. Required belt pull to is 2,178 pounds (lbs). Mechanical power required to drive the conveyor is 23.6 horsepower (HP). A 25 HP motor was installed. An alternating current (AC) power supply is defined by voltage, number of phases, and supply frequency. Since a power supply of 460 volts, 3 phase, 60 Hertz (460v/3ph/60Hz) was available, the motor was designed to run on that supply. Can the operator install a VFD to reduce the belt speed to 165 fpm and use the existing drive motor?

The diagram shows that 450 TPH of stone will fit within the trough of a 36 in wide conveyor belt at a belt speed of 165 fpm. Required belt pull is 3,760 lbs at a belt speed of 165 fpm and required mechanical power is 20.3 HP. Although a 25 HP was installed, the drive will fail because required mechanical power is 20.3 HP, but available motor power is 12.5 HP. In the frequency spectrum described above, motor rotor RPM is linearly proportional to power supply frequency. Although motor torque is nearly constant in the range of 30 Hz to 60 Hz, motor power is linearly proportional to power supply frequency. Therefore,

Available power = 25 HP x 30 Hz/60Hz = 12.5 HP

Required Power = 20.3 HP.