This blog describes several successful applications of Rulmeca Motorized Pulleys as hopper feeder conveyor drives. Hopper feeder conveyors have a unique loading condition due to the extra “drag” imparted onto the conveyor by material stored within the hopper.

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

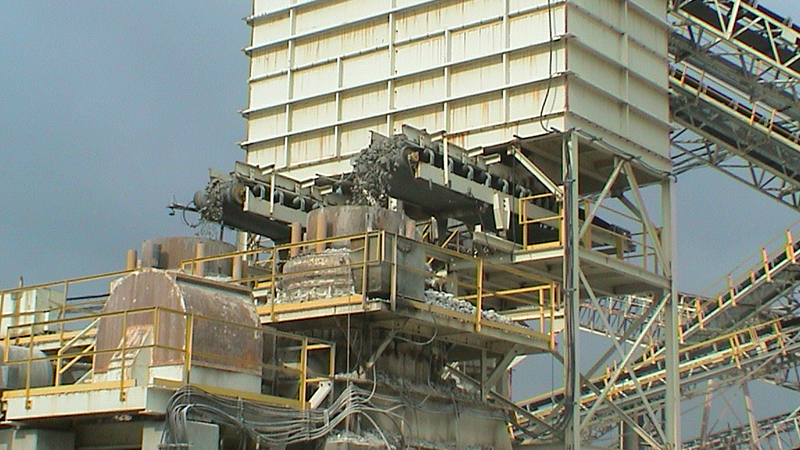

Two 15.75” diameter 5.5 HP Motorized Pulleys were installed to automatically “choke feed” tertiary gyratory crushers, working in combination with variable frequency drives (VFD) and optical sensors. Each pulley drives a 36” wide belt at a maximum speed of 120 FPM to transfer 4” minus product at 425 TPH. After testing the “automatic choke feed” concept for two years, this national aggregate producer incorporated Motorized Pulley driven hopper feeder conveyors at five additional quarries in the US. This concept networks a Motorized Pulley with an optical sensor and a VFD to automatically choke feed each gyratory crusher to optimize product size and throughput rate.

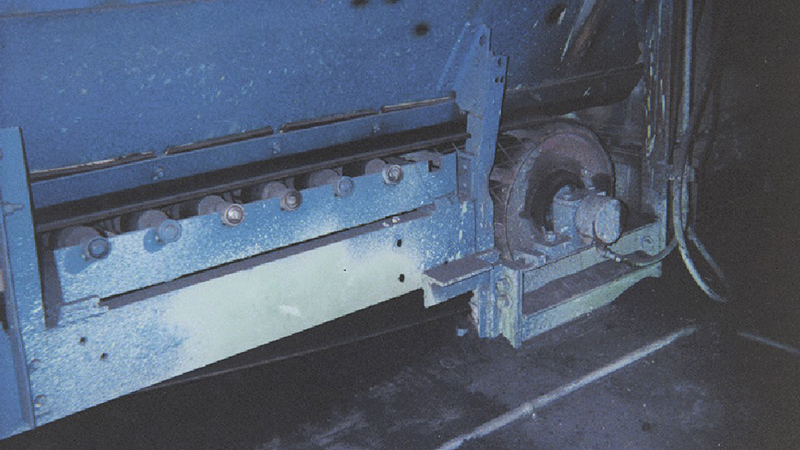

Installed at a US foundry in 1980, this 15.75” diameter 10 HP Motorized Pulley transfers recycled foundry sand to mold area at 150 TPH. Conveyor makes 30 start/stops per hour. Ambient environment is hot (>104º F) and contains a high percentage of airborne abrasive particulate. Photo taken in 1993, after 13 years of service. Technical Precaution: When installing motorized pulley in hot environment (>104º F), specify optional Class H motor windings and synthetic oil. Contact Rulmeca if ambient temperature will exceed 120º F.

Photo shows one of five hopper feeder conveyors beneath aggregate mixing bins installed at cement plant. Each 30” wide feeder belt is driven by an 8.5” diameter 4 HP Motorized Pulley at 200 FPM. Collector belt is driven by a 15.75” diameter 10 HP at 250 FPM. Technical Precaution: When designing hopper feeder drives always include material drag force in power calculations.

Taconite Processing Plant (USA) – Two limestone feeder belt drives beneath storage silo were converted from 20-year-old DC motors to AC-powered Motorized Pulleys. A VFD drives each 19.72” diameter 5.5 HP Motorized Pulley to a maximum of 120 FPM. Conversion enabled plant operator to eliminate exposed motors and gearboxes and replace SCRs, relays, and timer banks with VFDs in control panel. Technical Precaution: When driving Motorized Pulley with VFD on 460 volt 3 phase 60 Hz power supply, filter VFD output if Motorized Pulley is more than 30’ from VFD to avoid resonance-induced voltage spikes.