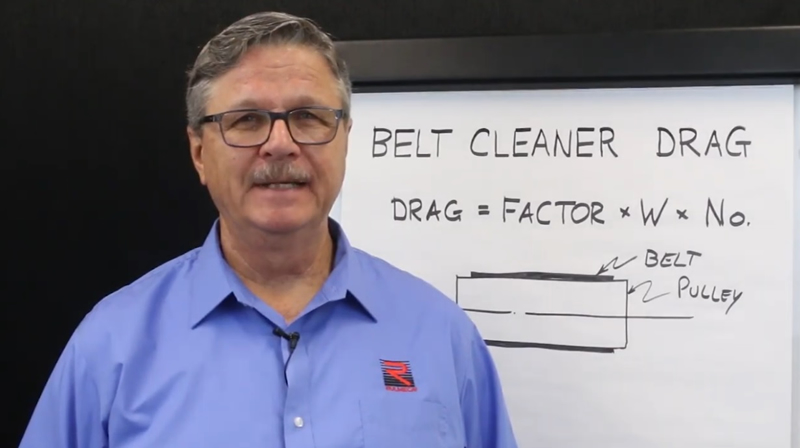

This “technical tip” answers how to calculate the drag force exerted on a bulk handling belt conveyor by a mechanical belt cleaner.

The Conveyor Equipment Manufacturers Association (CEMA) conveyor design manual states that belt cleaner drag may vary from 2 to 14 pounds per inch (lbs/in) of scraper-blade contact, depending upon the type of belt cleaner used, and recommends a drag value of 5 lbs/in of width of each blade of cleaner contact, if an actual value is unknown.

We can conservatively estimate belt cleaner drag by using 5 lbs/in of width of belt, rather than 5 lbs/in of cleaner contact. For example, if we have a pulley which has two cleaners on it, each at 24” wide each, cleaning a belt which is 30” wide, we can conservatively calculate the belt cleaner drag as follows.

Belt Cleaner Drag = 5 lbs/in of belt width x 30” of belt width x 2 belt cleaners

Belt Cleaner Drag = 300 lbs.

If the conveyor belt has a belt speed of 300 feet per minute (fpm), then we can calculate required power as follows.

Required Power = 300 pounds of drag x 300 fpm of belt speed

Required Power = 90,000 foot pounds per minute (ft-lbs/min).

Since 1 HP = 33,000 ft-lbs/min, required power to overcome belt cleaner drag may be calculated as follows.

Required Power = 90,000 ft-lbs/min/((33,000 ft-lbs/min)/HP)

Required Power = 2.7 HP

In this example, we need 2.7 HP to overcome belt cleaner drag. If these cleaners were added to a conveyor with a 10 HP drive system, then the extra drag would add 27% of the required power, which is significant. On the other hand, if they were added to a conveyor with a 300 HP drive system, the extra drag would be insignificant.

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

This 10 minute video explains how to calculate belt cleaner drag in more detail.