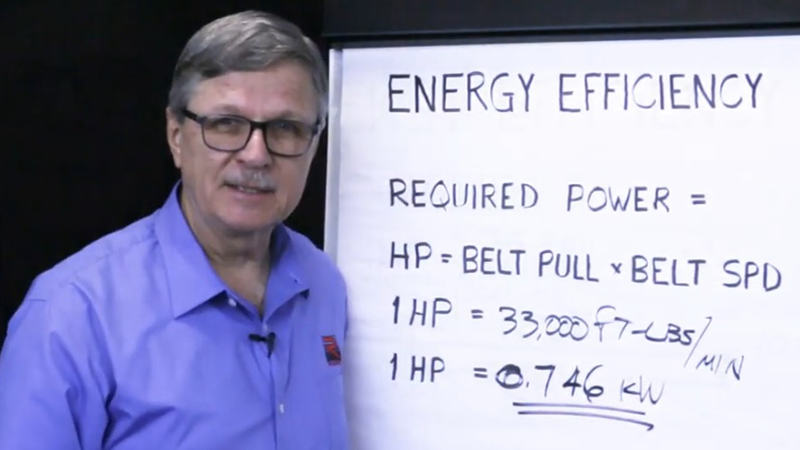

This “technical tip” answers how to calculate conveyor drive electrical efficiency.

By definition, 1 HP = 0.746 kW. Therefore, a change in required mechanical drive power can be easily converted into a change in required electrical power. Since cost/kW-hour and annual operating hours are known for each facility, a change in required mechanical power can be converted into a specific change in kW-hr/year and energy cost/year, using the equations shown below.

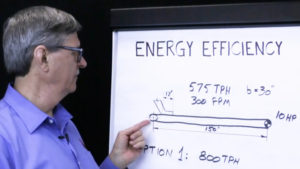

If, for example, a conveyor operator opted to replace an inefficient, slow, fully-skirted conveyor, with a conveyor using a conventional skirtboard and faster belt speed, the electrical and cost savings may be calculated as follows:

Fully-skirted, 30″ wide conveyor belt, handling 800 tph at 300 fpm, requires 18.7 HP

Standard skirt, 30″ wide conveyor belt, handling 800 tph at 415 fpm, requires 12.1 HP

If the conveyor runs 24 hours/day and 365 days per year, the difference in electrical power consumption rates may be calculated as follows:

Difference in mechanical power = 18.7 HP – 12.1 HP = 6.6 HP

Difference in electrical power = 6.6 HP x 0.746 kW/HP = 4.9 kW

Difference in electrical power consumption rates = 4.9 kW x 24 hrs/day x 365 days/ yr = 42,924 kW- hrs/yr

If the facility pays the electric utility $0.10/kW-hr, then the annual cost savings to make the conversion may be calculated as follows:

Annual cost savings = 42,924 kW-hrs/yr x $0.10/kW-hr = $4,292/yr.

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

This 10 minute video explains how to calculate conveyor drive efficiency in more detail.