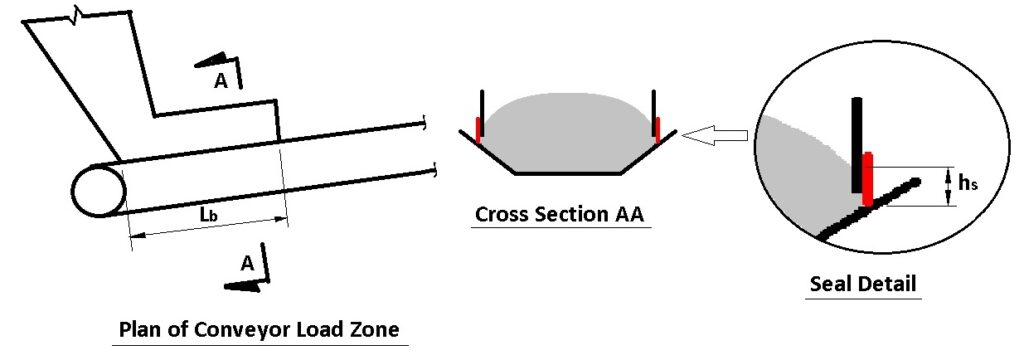

This “technical tip” answers how to calculate the drag force exerted on a bulk handling belt conveyor by a skirtboard system. Determining skirtboard drag force is important note only when designing a new conveyor system, but also when modifying an existing skirtboard to accommodate a change in the material’s handling rate. The force consists of two components: material drag on the skirtboard and seal drag on the conveyor belt.

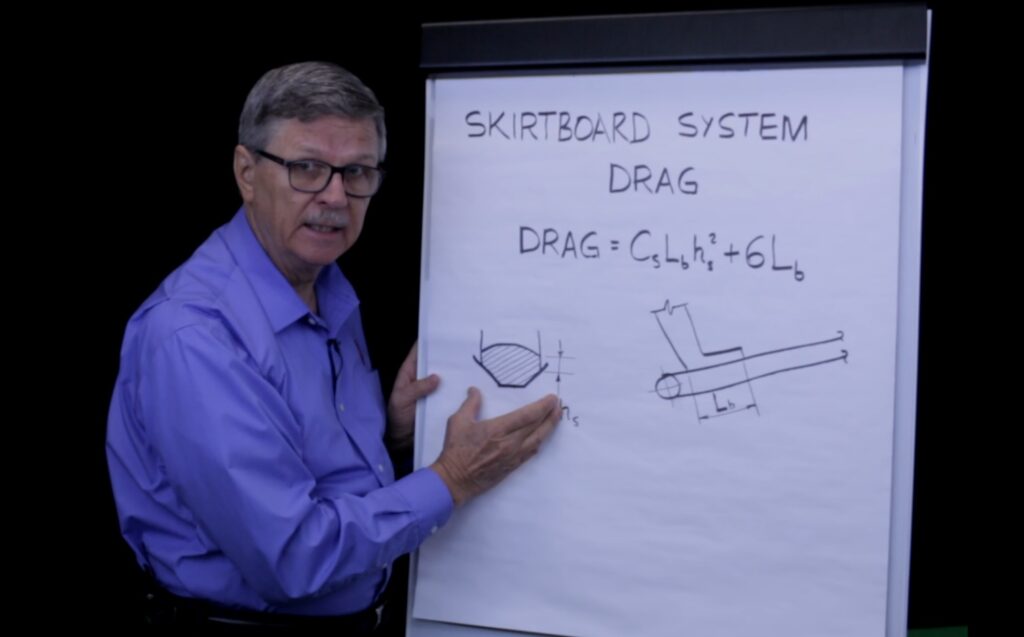

Skirtboard Drag = T = CsLbhs2,+ 6Lb,

where terms are defined by the Conveyor Equipment Manufacturers Association (CEMA), using the historical method.

Material drag on the skirtboard equals the frictional coefficient for the material being handled times the length of the skirtboard, in feet, times the square of the depth of material rubbing on the board, in inches.

Skirtboard seal drag may be approximated, where the actual seal type is unknown, by multiplying 6 times the length of the skirtboard. That assumes seal drag = 3 lbs/ft of skirt seal on a two-sided skirt seal system.

For example, assume the material being handled is iron ore, the skirtboard is made from steel (which is very typical), the length of the zone is 15 feet, and the depth of material within that zone is 4”. CEMA provides a frictional coefficient of 0.276 for iron ore rubbing against a steel skirtboard.

To calculate the material frictional drag, use this equation:

0.276 x 15′ x (4″)2 = 0.276 x 15 x 16 = 66 lbs of material drag

To calculate seal drag, use this equation:

3 lbs/ft of board x 2 boards x board length of 15 feet = 90 lbs of seal drag

The total of these frictions equals 156 lbs.

66 lbs + 90 lbs = 156 lbs

Assume, in this example, that belt speed = 600 feet per minute. Therefore, required power to overcome skirtboard drag may be calculated as follows:

156 lbs x 600 fpm = 93,600 ft-lbs/min

Since one HP = 33,000 ft-lbs/minute, required power to overcome skirtboard drag 2.8 HP, as follows:

(93,600 ft-lbs/min)/(33,000 ft-lbs/min per HP) = 2.8 HP

If the conveyor system was relatively small and the total drive was 10 HP, 2.8 HP is a significant part of that drive power requirement (i.e. 28%), but if the conveyor is quite long, requiring a drive power of 300 HP, then 2.8 HP is relatively insignificant compared with the total power required in that system (i.e. 2.8%).

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

This 10 minute video explains how to calculate skirtboard drag in more detail.