This “technical tip” answers how to calculate required conveyor belt pull and drive power for a horizontal, slider bed supported package handling conveyor. It is based on our most popular YouTube video, which has more than 50,000 views.

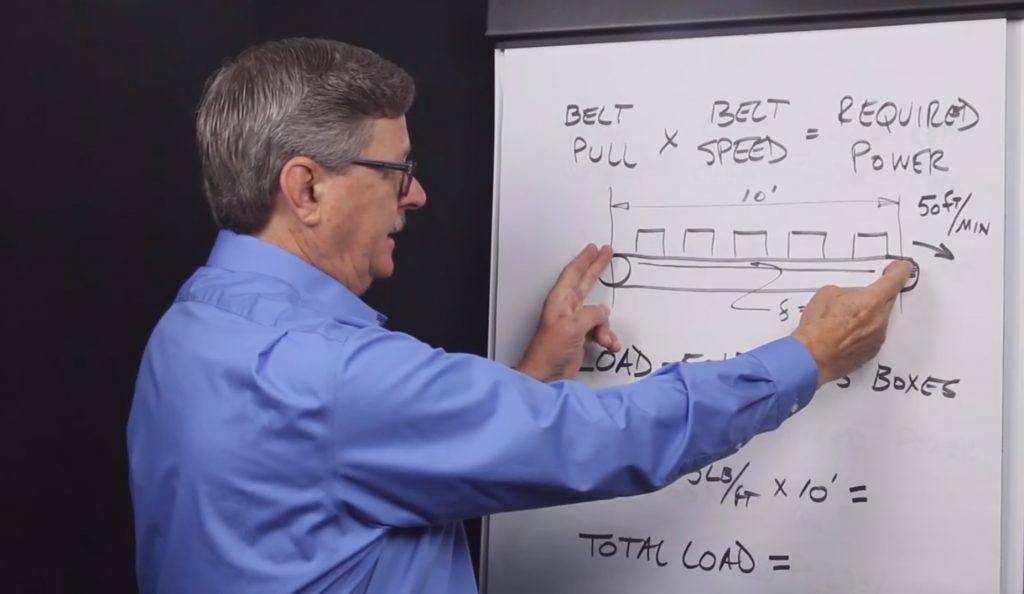

Required Power = Belt Pull x Belt Speed

The belt pull required to move packages on a slider bed conveyor equals the total weight of all packages, plus the weight of the belt times the coefficient of friction between the bottom of the conveyor belt and the top of the slider bed.

If a 10 foot long conveyor moves five 50 pound boxes simultaneously at a belt speed of 50 feet per minute on a conveyor belt with a weight of 3 lbs/ft, on a slider bed with a frictional coefficient of 0.5, then the belt pull is calculated as follows.

First, calculate total weight.

Total Weight = 5 packages x 50 lbs/package + 10 feet of belt x 3 lbs/ft

Total Weight = 250 lbs + 30 lbs = 280 lbs

Then, calculate belt pull. Belt pull equals total weight times frictional coefficient between the bottom of the belt and the top of the slider bed.

Belt Pull = Total Weight x frictional coefficient

Belt Pull = 280 lbs x 0.5

Belt Pull = 140 lbs

Then, convert this to required power.

Required Power = Belt Pull x Belt Speed

Required Power = 140 lbs x 50 fpm = 7,000 ft-lbs/min

One horsepower (HP) equals 33,000 ft-lbs/min. Therefore, required power can be converted as follows.

Required Power = (7,000 ft-lbs/min)/(33,000 ft-lbs/min per HP)

Required Power = 0.2 HP

ABOUT RULMECA CORPORATION

We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

This 5 minute video explains how to calculate required conveyor belt pull and drive power in more detail.