We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

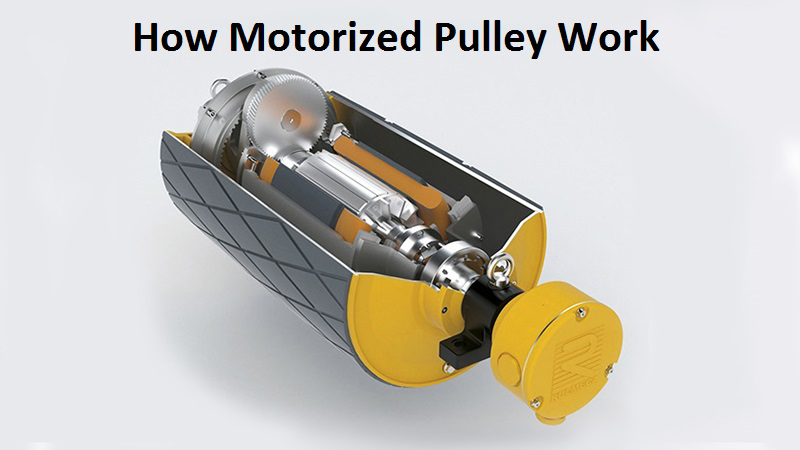

HOW MOTORIZED PULLEYS WORK (PART 1 OF 6)

This video explains how Motorized Pulleys work and provides an introduction to the company’s six-part tutorial on how to troubleshoot Rulmeca Motorized Pulleys. Use this video in conjunction with our growing library of tutorials on how to design and maintain bulk handling belt conveyors.

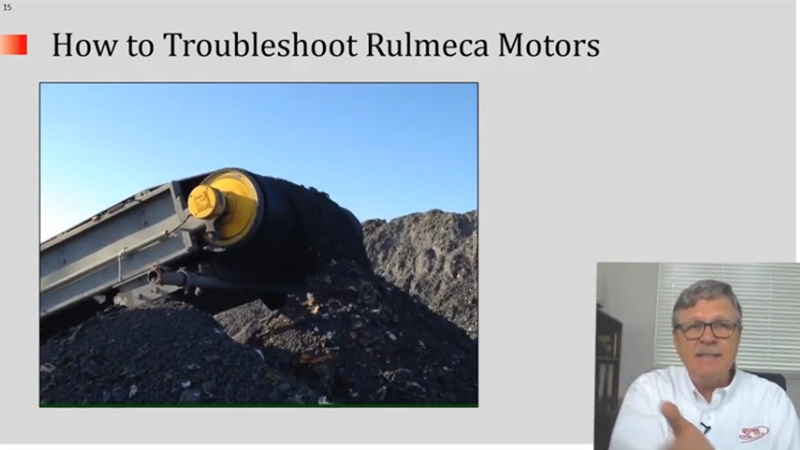

This video will explain how a Rulmeca Motorized Pulley, three phase, squirrel cage, AC electric induction motor works, and how to troubleshoot it. These hermetically-sealed internally-powered conveyor drives are ideal in harsh operating conditions, especially when space is limited, and personnel safety is a concern.

In this six-part video tutorial we will review drive power vs. belt pull, basic motor components, current flow in a stator, current flow vs. drive power, overcurrent and thermal protection, common causes of motor damage, how to check motors, and examples of damaged motors.

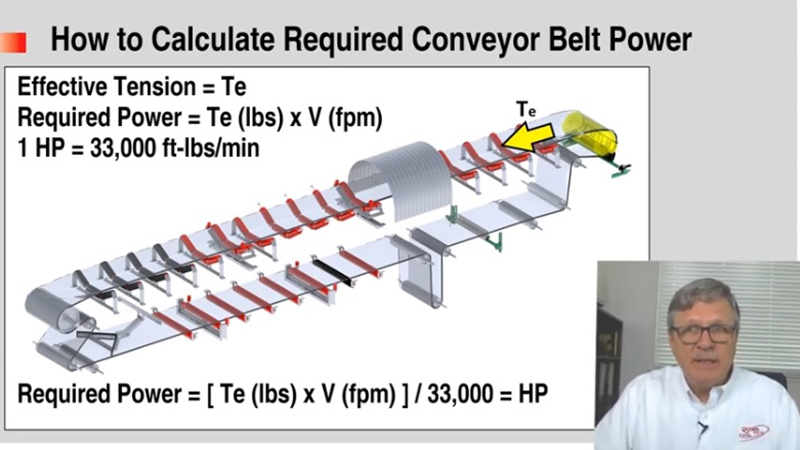

As presented in a previous Rulmeca video tutorial, we explained that it is essential to calculate effective tension (Te) or “belt pull” required to move a bulk handling conveyor, because knowing the belt pull will enable the designer to calculate the required power.

We know that once we have calculated Te in pounds (lbs) for a particular set of conditions and we know the belt speed in feet per minute (fpm), we can calculate required drive power using the equations below.

Required Power (in ft-lbs/min) = Te (in lbs) x V (in fpm)

1 HP = 33,000 ft-lbs/min

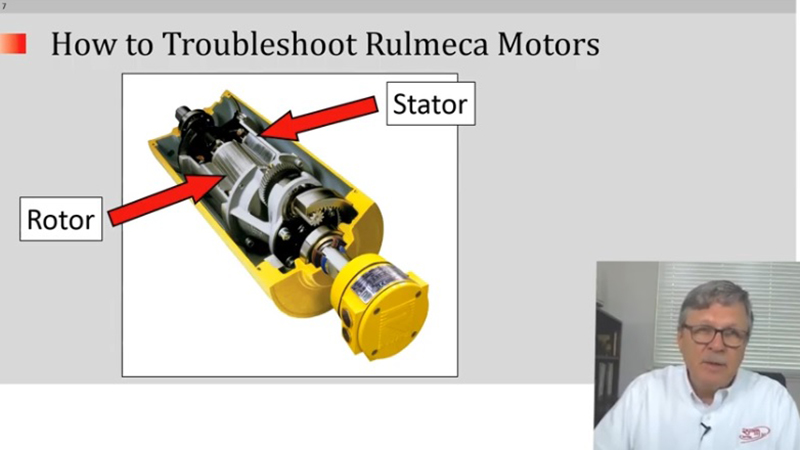

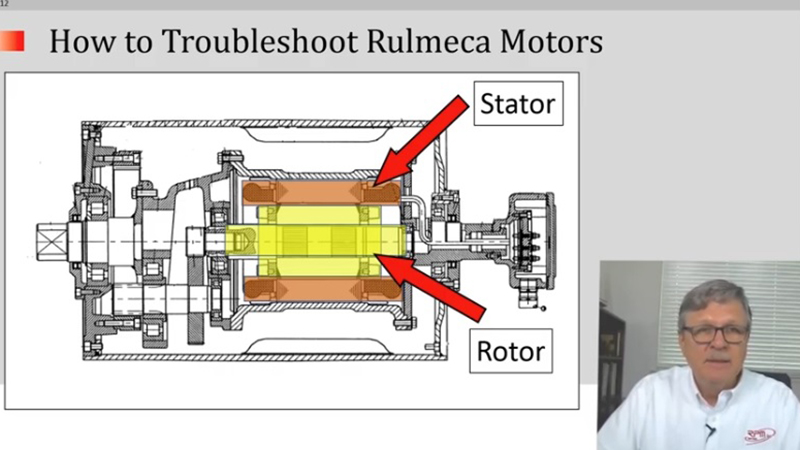

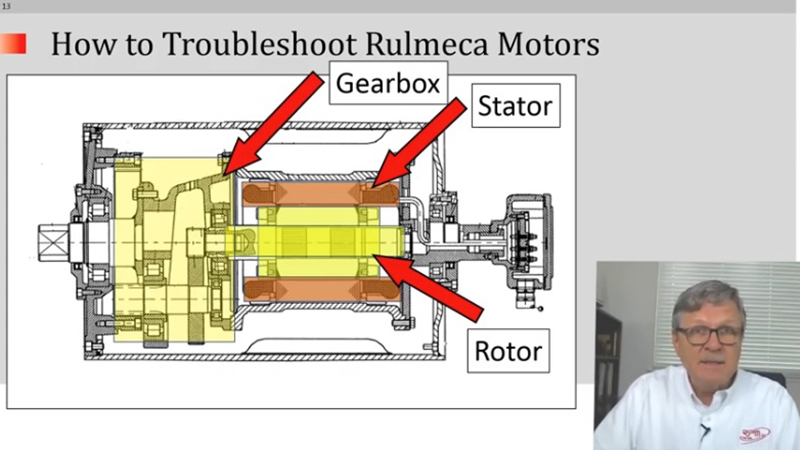

The basic components of an AC electric motor are a stator and a rotor. Notice that in a Rulmeca Motorized Pulley the rotor is directly coupled to the pulley shell through the gearbox.

This cross-sectional diagram illustrates the stator and rotor within a Rulmeca Motorized Pulley.

This cross-sectional diagram shows the motor directly coupled to either a two stage or a three-stage gearbox. The motor stator is “stationary” and the motor rotor “rotates” on two internal bearings, which are mounted in each of the two sides of the motor frame.

All Rulmeca Motorized Pulleys contain a certain quantity of oil. The oil serves to lubricate all of the mechanical parts and continuously cool the motor by pulling the heat away from the stator and transferring that heat into the conveyor belt through the pulley shell.

As the conveyor belt wraps around the face of the pulley, it continuously pulls heat from the face of the pulley and takes it away, dissipating the heat into the atmosphere.

We hope you enjoyed this tutorial. For more informative tutorials, please subscribe to our YouTube channel. Thank you very much.