We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

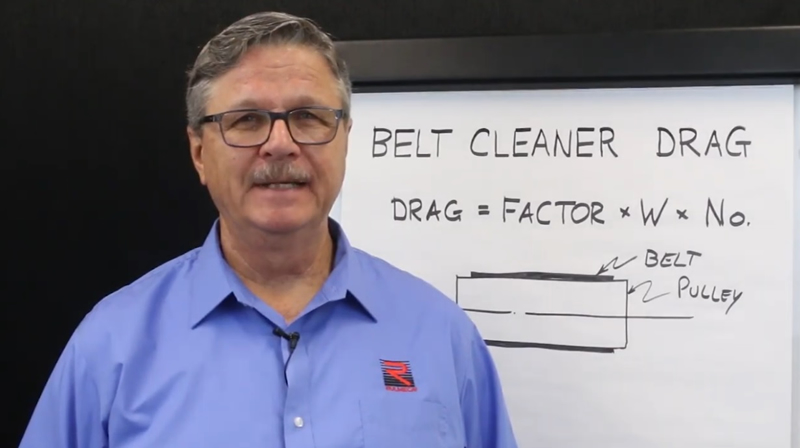

HOW TO CALCULATE CONVEYOR BELT CLEANER DRAG AND REQUIRED POWER

This video explains how to calculate belt conveyor cleaner drag and the power required to drive it. Based on the Conveyor Equipment Manufacturers Association (CEMA) conveyor design guide, this video presents useful equations and standard parameters which will help users to select appropriately-sized conveyor drive systems. Use this video in conjunction with our growing library of tutorials on how to design and maintain bulk handling belt conveyors.

This tutorial covers why belt cleaners are used on bulk handling conveyors, what general types of belt cleaners are available, how to calculate belt cleaner drag, and how to calculate the belt power required to overcome belt cleaner drag.

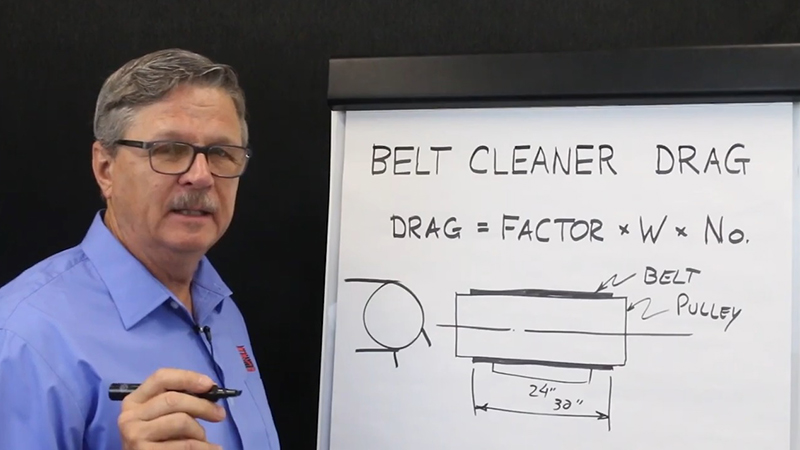

Belt cleaners remove carryback from the underside of conveyor belts. Typically, belt cleaners are installed just below the horizontal centerline on the face of the pulley or beneath the pulley.

Carryback is removed from the underside of conveyor belts to extend conveyor component life, especially that of idlers and belt, and to improve safety for plant personnel working near the belts. Without an effective belt cleaner, a bulk handling conveyor will drop fine material from the bottom of the return strand beneath the entire length of the conveyor.

This carryback material will also accumulate beneath each return roller, as shown here. If not removed, this accumulating material will eventually impinge on the return idlers and the belt and damage them.

A variety of belt cleaners are available from simple, single, mechanical scrapers, which are either spring loaded or counter-weighted, to more complicated multiple scrapers, rotating brushes, and belt washing systems.

Belt scraper material may be anything from used conveyor belt, which is not recommended, to molded urethane, to thin tungsten carbide blades. Some manufacturers offer broad blades while others insist on the advantages of thin blades. When adding one or more cleaners to a bulk-handling conveyor, how can a conveyor operator be certain to have enough power to drive the conveyor?

The Conveyor Equipment Manufacturers Association (CEMA) conveyor design manual states that belt cleaner drag may vary from 2 to 14 pounds per inch (lbs/in) of scraper-blade contact, depending upon the type of belt cleaner used, and recommends a drag value of 5 lbs/in of width of each blade of cleaner contact, if an actual value is unknown.

We can conservatively estimate belt cleaner drag by using 5 lbs/in of width of belt, rather than 5 lbs/in of cleaner contact. For example, if we have a pulley which has two cleaners on it, using the same example as this, and we have the carrying strand coming in this direction and the return strand going in that direction, we could put a pre-cleaner here and we can put a secondary cleaner here.

Let’s say they are 24” wide each, but the belt 30” wide. We can conservatively calculate the belt cleaner drag in this example as follows.

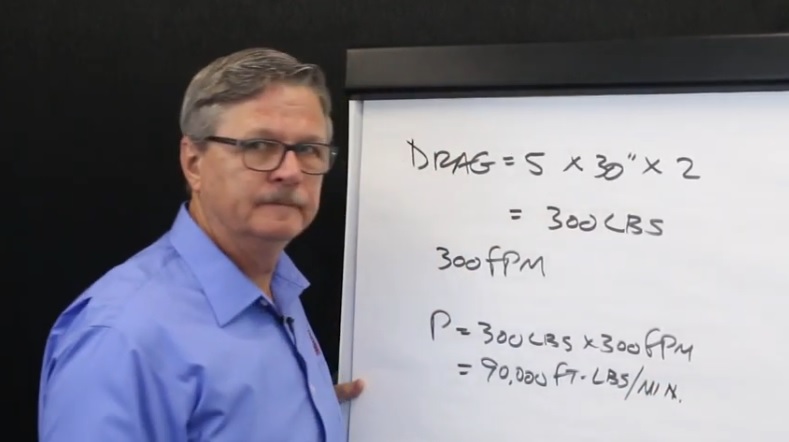

Belt Cleaner Drag = 5 lbs/in of belt width x 30” of belt width x 2 belt cleaners

Belt Cleaner Drag = 300 lbs.

How do we calculate power required to overcome this drag? Continuing with this example, if we say that the conveyor belt has a belt speed of 300 feet per minute (fpm), we can calculate required power as follows.

Required Power = 300 pounds of drag x 300 fpm of belt speed

Required Power = 90,000 foot pounds per minute (ft-lbs/min).

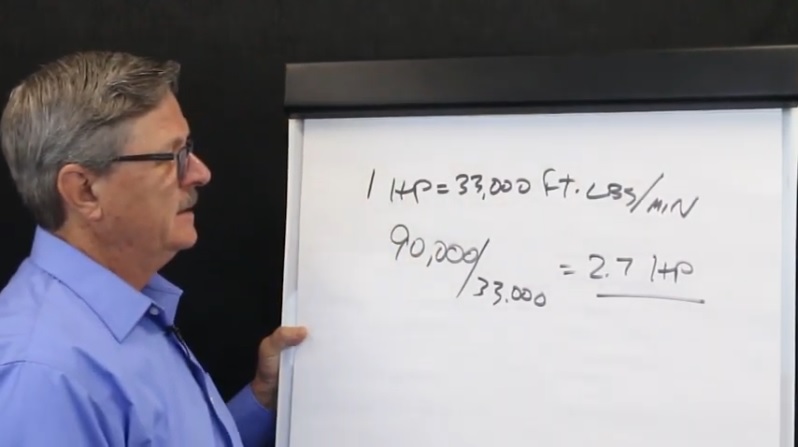

How do we convert 90,000 foot pounds per minute into a useful unit of measure? We know that 1 HP = 33,000 ft-lbs/min

Therefore, in our example, required power to overcome belt cleaner drag may be calculated as follows.

Required Power = 90,000 ft-lbs/min/((33,000 ft-lbs/min)/HP)

Required Power = 2.7 HP

In this example, we need 2.7 HP to overcome belt cleaner drag. If these cleaners were added to a conveyor with a 10 HP drive system, then the extra drag would add 27% of the required power, which is significant. On the other hand, if they were added to a conveyor with a 300 HP drive system, the extra drag would be insignificant.

We hope you found this short tutorial useful. For more tips on conveyor drive design and maintenance, go to rulmecacorp.com or subscribe to our YouTube channel. Thank you very much.