We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

HOW TO CALCULATE ENERGY EFFICIENCY IN CONVEYORS

This video provides techniques on how to calculate electrical energy consumption and compare the efficiency between two bulk handling belt conveyors. Use this video in conjunction with our growing library of tutorials on how to design and maintain bulk handling belt conveyors.

Energy efficiency is a hot topic these days. If you don’t believe that, then try to buy a light bulb at your local store. It’s no longer possible to simply go and select a 100 watt bulb. Now you need to familiarize yourself with terms such as Kelvins, lumens, estimated yearly energy costs, energy used, and terms such as that. This video will take some of the mystery out of that topic and enable conveyor operators and designers to convert mechanical power usage to electrical power consumption. It’ll show how a reduction in power can be converted to a reduction in kilowatt-hours (kW-hrs) per year and, therefore, a reduction in dollars per year.

Other Rulmeca videos show how to calculate required belt tension, how to calculate belt cleaner drag, how to calculate skirtboard system drag, and how to calculate hopper feeder drag. This video will show how to improve energy efficiency by reducing required belt tension, also known as effective tension or Te.

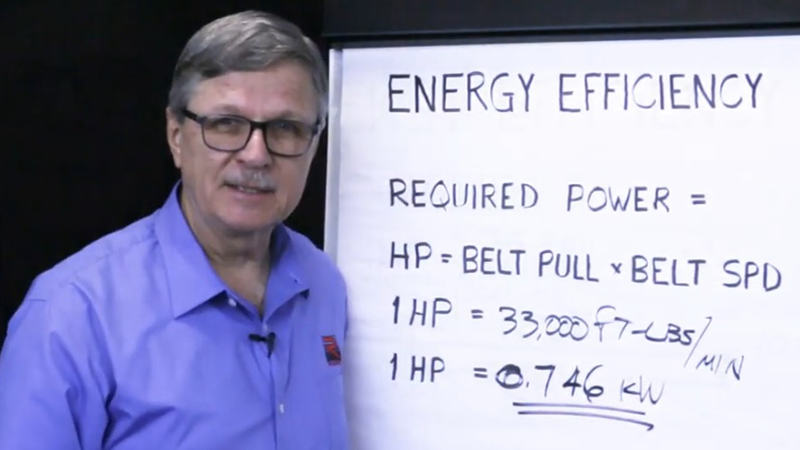

Here are some key terms we must define at the beginning of this presentation. We know that required power equals the product of belt pull and belt speed. Required power equals pounds (lbs) of belt pull times feet per minute (fpm) of belt speed.

By definition,

One horsepower = 33,000 foot-pounds per minute, or

1 HP = 33,000 ft-lbs/min

And here is another key definition:

1 HP = 0.746 kilowatts = 0.746 kW.

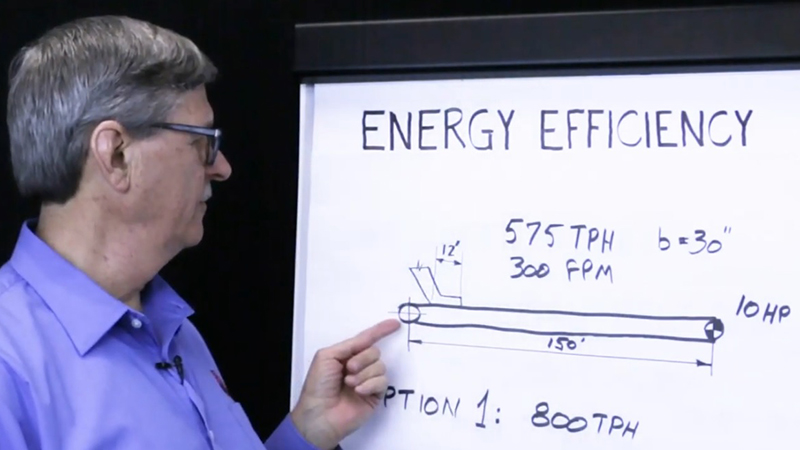

A previous Rulmeca video showed how a 150 foot long conveyor with a 30 inch wide belt and a 10 HP drive system, originally installed to carry 575 tons per hour (tph) at 300 fpm, could be upgraded to handle 800 tph. Option one recommended that the conveyor be fully skirted while maintaining a 300 fpm belt speed. Option two recommended the use of a standard skirt (12 feet long) with a 415 fpm belt speed.

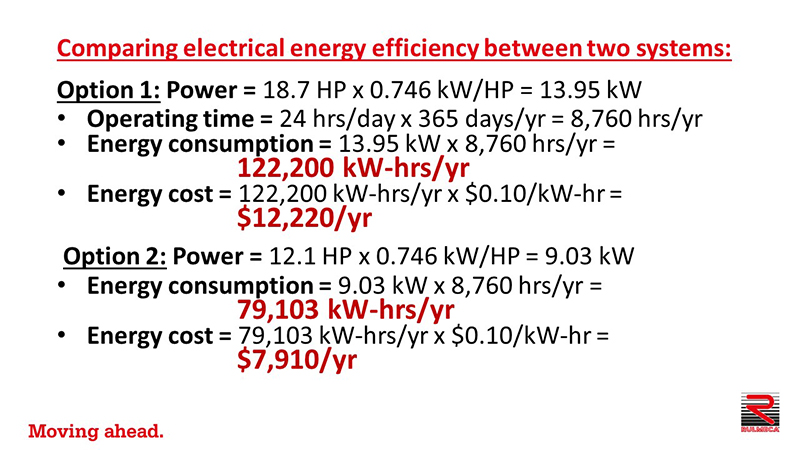

Each option required the purchase of a new drive system. The previous video showed that if the facility runs 24 hours per day, 365 days per year, and if the electric utility charges $0.10 per kilowatt-hour (kW-hr), the two options would compare as follows:

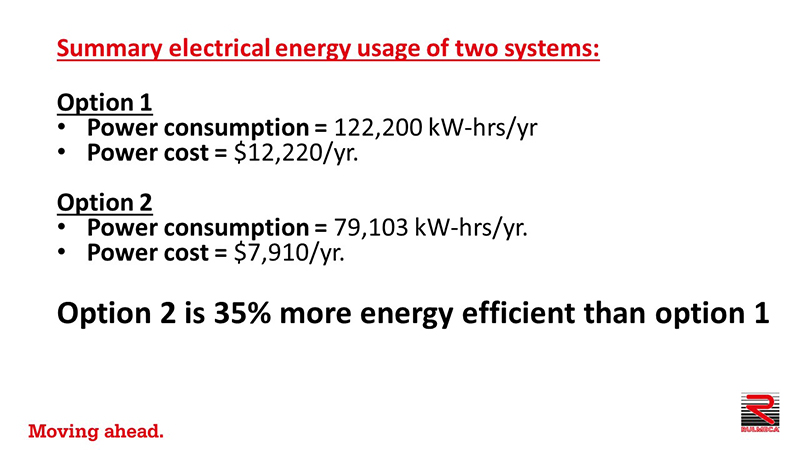

Option one would have a power consumption of 122,200 kW hours per year (kW-hrs/yr) at an annual cost of $12,220.

Option two would have a power consumption of 79,103 kW-hrs/yr at an annual cost of $7,910.

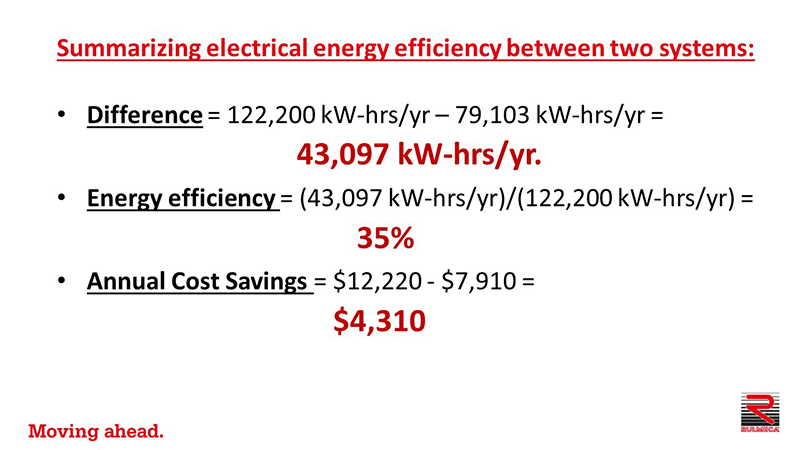

Clearly, in this instance, option two is 35% more energy-efficient than option one.

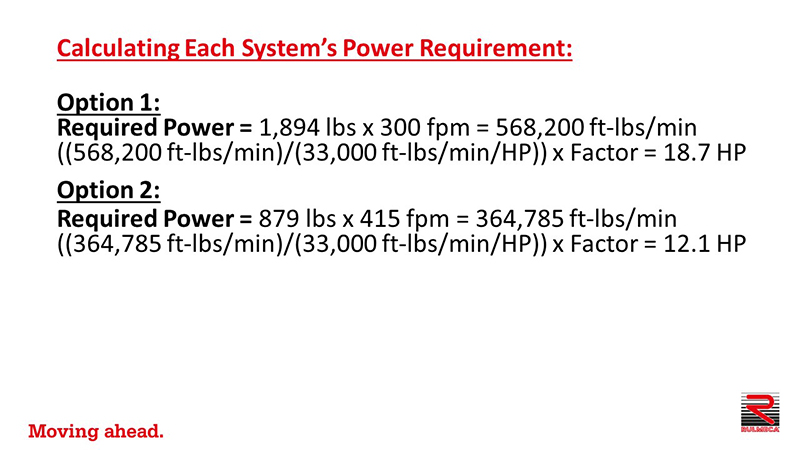

Here is how to calculate each system’s power requirement: Option one’s required power equals a belt pull of 1,894 pounds times a belt speed of 300 fpm, giving us a power requirement of 568,200 ft-lbs/min. We divide that by 33,000 ft-lbs/min per HP. We apply a factor and we determine that the required power equals 18.7 HP.

Option two’s required power equals a belt pull of 879 pounds times a belt speed of 415 fpm for a power requirement of 364,785 ft-lbs/min. We divide that by 33,000 ft-lbs/min per HP, apply a factor, and determine that the required power equals 12.1 HP. Our constant factor enables us to accommodate such things as: ambient temperature, altitude, drive pulley bearing friction loss, gear loss, and things such as that.

Here is how to compare the efficiency of the two systems: Option one has a required power of 18.7 HP. We simply multiply that by 0.746 kW per HP, and we determine that the power requirement is 13.95 kW. With an operating time of 8,760 hours per year, we simply multiply the kW by the operating hours and we determine that the required energy consumption is 122,200 kW-hrs/yr. At an electrical utility charge of 10 cents per kW-hr, we conclude that the power cost is $12,220 per year.

In option two we know that the required power equals 12.1 HP. We simply multiply that by 0.746, determine that we require 9.03 kW. We then multiply that by 8,760 hours per year and we determine that the energy consumption is 79,103 kW-hrs/yr. At 10 cents per kW-hr that equates to an annual electric power cost of $7,910. In conclusion, we have shown that the faster belt speed and the shorter skirt has an energy efficiency of 35% when compared with a fully-skirted slower conveyor.

Here’s how to calculate the difference in power consumption: We simply subtract 79,103 kW-hrs/yr from 122,200 kW-hrs/yr to derive an answer of 43,097 kW-hrs/yr. Dividing that by 122,200 yields an energy efficiency of 35%. The annual cost savings is nothing more than the difference between the two annual numbers. $12,220 and minus $7,910 equals $4,310 per year.

It’s important to note that in this video we have assumed that the plant would be operating 24 hours per day and 365 days per year. Your operating conditions may be different. It’s also important to note that we have, to simplify the explanation, assumed that the conveyor runs 100% of the time at full power. This, of course, is an oversimplification. However, it’s a handy technique to determine what the worst case condition of power consumption would be.

You can now use these techniques to evaluate conveyor efficiency improvements such as replacing old two transmission drive systems with newer single transmission drives or adding hopper pressure relief to the openings of hoppers. These topics will be covered in future videos.

We hope you found this short tutorial useful. For more conveyor design and maintenance tips, go to Rulmecacorp.com or subscribe to our YouTube channel. Thank you very much.