We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

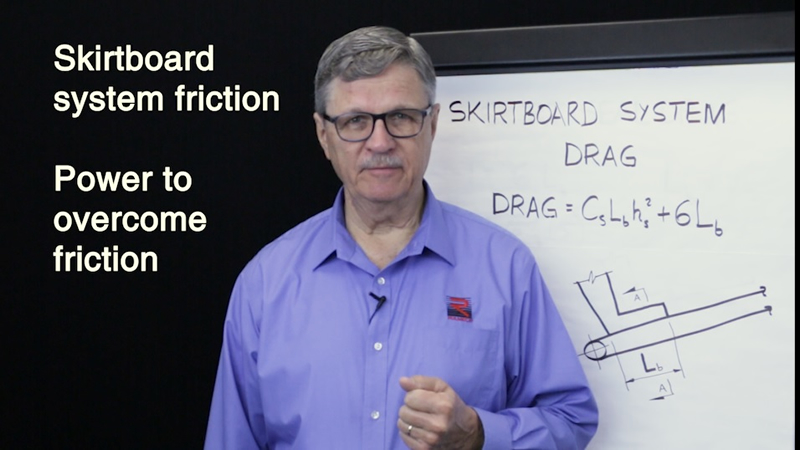

HOW TO CALCULATE CONVEYOR SKIRTBOARD DRAG AND REQUIRED POWER

This video explains how to calculate belt conveyor skirtboard system frictional drag and the power required to drive it. Use this video in conjunction with our growing library of tutorials on how to design and maintain bulk handling belt conveyors.

This video covers conveyor skirtboard systems, how to calculate the friction they cause, and how to calculate the power required to overcome that friction. Conveyor skirtboard systems are used to contain material as it is transferred from one point onto a moving conveyor, stabilizing it within the trough in the skirt zone. Normally, skirt zone length (Lb) is short compared with the overall length of the conveyor because its purpose is to contain material and stabilize it within the trough. Sometimes it is necessary to fully skirt a conveyor because either the conveyor has multiple loading points or the material will not stabilize within the trough.

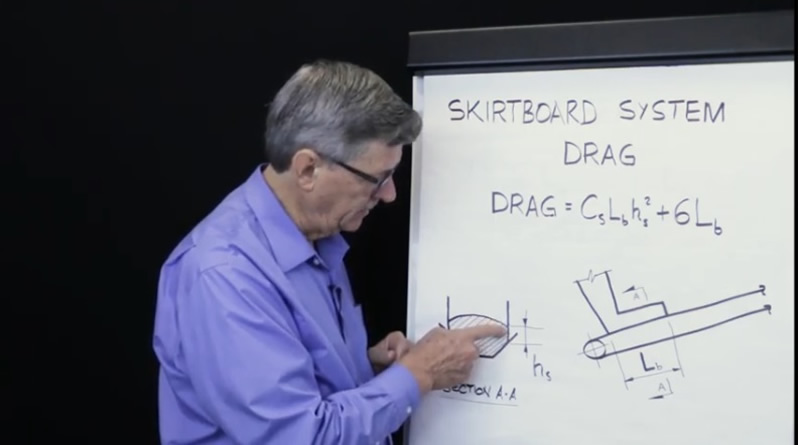

Cross section AA shows material within the skirtboard zone and two important things. One is the area where material rubs against the skirtboard and the other is the area where the skirtboard seal system rubs on the conveyor belt. An important dimension is hs, the depth of the material within the skirt zone where it rubs against the skirtboard. The two components of skirtboard system friction are: material frictional drag and skirtboard seal drag. To calculate material frictional drag within a skirtboard system, the Conveyor Equipment Manufacturers Association (CEMA) developed the equation:

T = CsLbhs2,+ 6Lb

CEMA has also published a list of frictional coefficients, which can be used for a variety of materials.

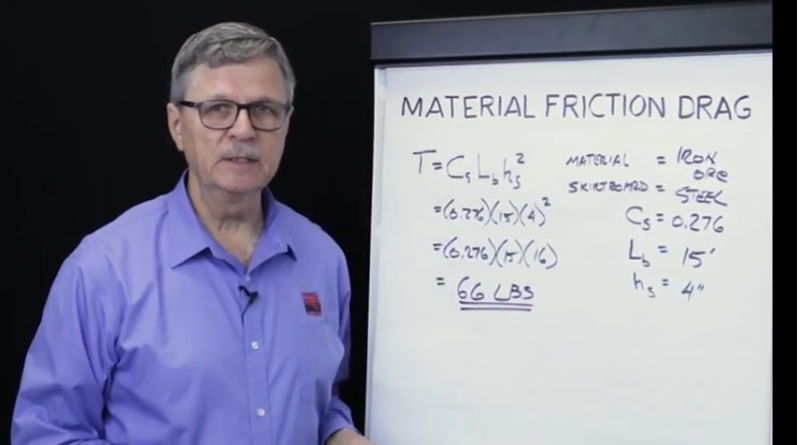

In this example, we will “move” iron ore. To calculate frictional drag from the iron ore rubbing against the skirtboard, multiply the frictional coefficient times the length of the skirtboard times the square of the material depth within the skirt zone. In this example, the material is iron ore, the skirtboard is made from steel (which is very typical), the length of the zone is 15 feet, and the depth of material within that zone is 4”. CEMA gives a frictional coefficient of 0.276 for iron ore rubbing against a steel skirtboard. To calculate the material frictional drag, use this equation:

0.276 x 15′ x (4″)2 = 0.276 x 15 x 16 = 66 lbs.

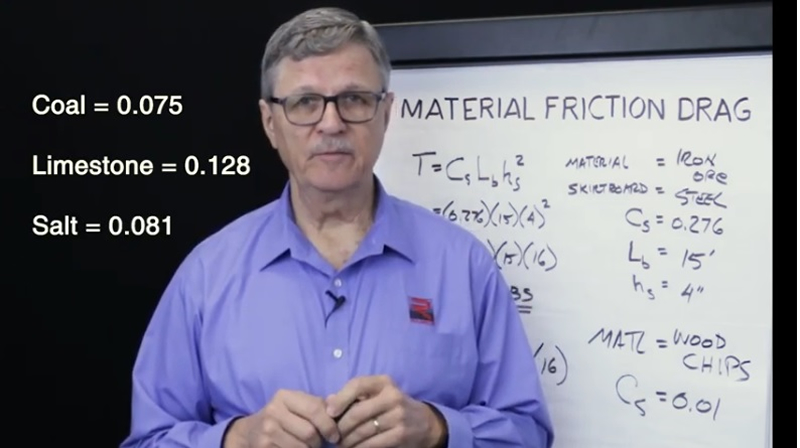

CEMA gives a frictional coefficient of 0.01 for wood chips. To calculate the drag for this material, use the equation:

0.01 x 15′ x (4″)2 = 0.01 x 15 x 16 = 2.4 lbs.

Notice that the frictional coefficient of iron ore is 27.6 times higher than that for wood chips. Therefore, the drag is 27.6 times higher, 66 lbs compared with 2.4 lbs.

CEMA gives a list of frictional coefficients to make it convenient to do material frictional drag analysis. For example, bituminous coal has a frictional coefficient of 0.075, limestone has a frictional coefficient of 0.128, and salt has a frictional coefficient of 0.081.

Notice how sensitive the results are to the material depth. Keep all the parameters the same as the iron ore case, but set the depth of material equal to 8” instead of 4”. Now material frictional drag =

0.276 x 15 x (8″)2 = 0.276 x 15 x 64 = 265 lbs

Note that when the iron ore has a depth of 8” instead of 4” in the zone, the material frictional drag equals 265 lbs instead of 66 lbs. That is because the result is proportional to the square of the ratio of the depths. In other words, 8″/4″ = 2 and 22 = 4. Therefore, the 8″ friction is 4 times the 4″ friction. If we compare the frictions of a 9” vs a 3” depth of material, the 9″ friction is 9 times the 3″ friction because (9/3)2 = 9.

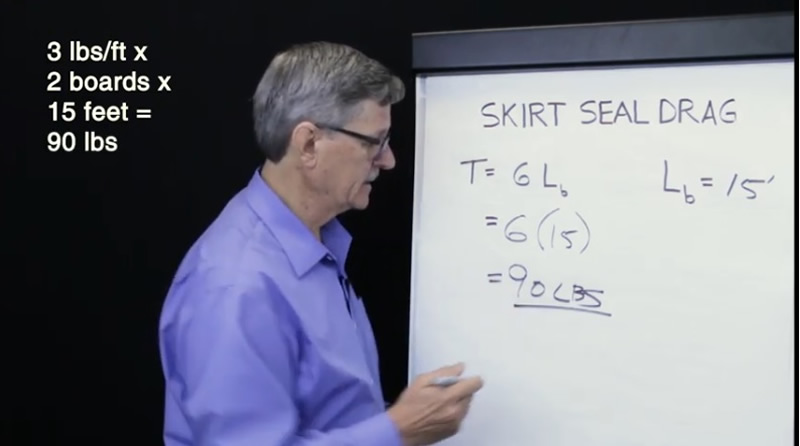

To calculate skirt seal drag for conventional seals CEMA provides the equation

T = 6Lb

A variety of flexible seals are available, including: vertical, perpendicular, oblique, parallel, and the so-called “contact-less” skirt seal system. CEMA recommends using a seal drag value of 3 lbs/foot of seal. In the 15′ skirt zone example, seal drag = 6 x 15 = 90 lbs. In other words,

3 lbs/ft of board x 2 boards x board length of 15 feet = 90 lbs of seal drag

Having calculated material frictional drag and skirt seal system drag, we can calculate total drag and, therefore, the power required to overcome this friction. In the example of moving iron ore with a frictional coefficient of 0.276 with a material depth of 4″ within a skirtboard 15 feet long, we have a material frictional drag of 66 lbs and a conventional rubber seal drag of 90 lbs. The total of these frictions equals 156 lbs.

66 lbs + 90 lbs = 156 lbs

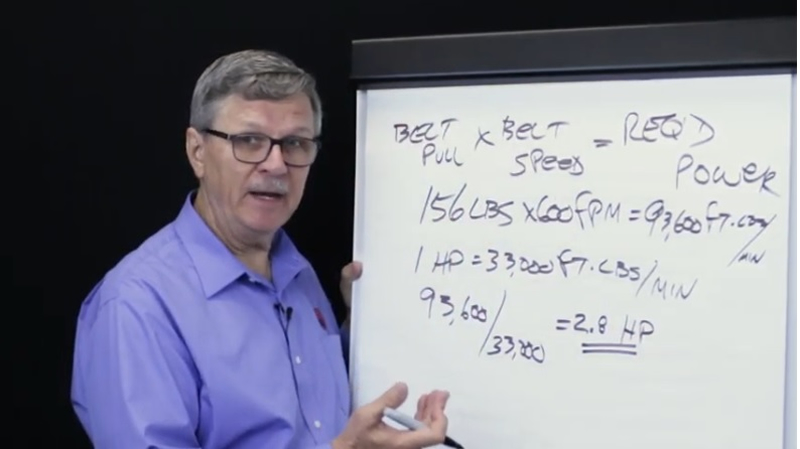

Having calculated the total drag of the skirtboard system, we can calculate the drive power required to overcome that friction because belt pull times belt speed equals the required power. Total skirtboard drag = 156 lbs. Assume, in this example, that belt speed = 600 feet per minute. We multiply those two numbers and we get a product of 93,600 ft-lbs/min, as follows

156 lbs x 600 fpm = 93,600 ft-lbs/min

How do we convert that to a useful unit of measure? One HP = 33,000 ft-lbs/minute. So, simply dividing 93,600 by 33,000 we can determine that the power required to overcome the skirtboard system drag is 2.8 HP, as follows

(93,600 ft-lbs/min)/(33,000 ft-lbs/min per HP) = 2.8 HP

If our conveyor system was relatively small and the total drive was 10 HP, 2.8 HP is a significant part of that drive power requirement (i.e. 28%). On the other hand, if our conveyor is quite long, requiring a drive power of 300 HP, then 2.8 HP is relatively insignificant compared with the total power required in that system (i.e. 2.8%). We hope you’ve found this short tutorial useful. For more tips on conveyor design and maintenance, go to rulmecacorp.com or subscribe to our YouTube channel. Thank you very much.