We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

HOW TO COMPARE REQUIRED AND AVAILABLE POWER IN CONVEYOR DRIVES WHEN USING A VFD

Conveyor designers and operators should be aware that three phase AC electric motor power is linearly proportional to power supply frequency. Therefore, it is necessary to always compare required and available power at all relevant rates, including all planned belt speeds and all planned materials handling rates. This principle not only applies to continuous flow conveyors, but also to metered flow conveyors.

We will examine rates and powers in four examples. In continuous flow, we will examine required and available powers when a given belt speed is reduced. In metered flow, we will examine required and available powers when a given belt speed is increased.

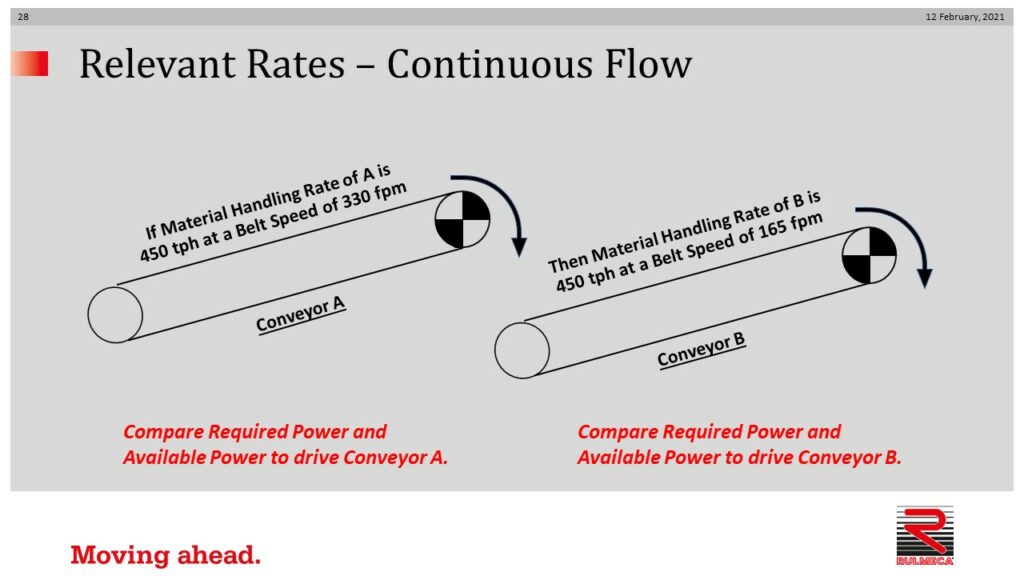

In continuous flow, material handling rate remains constant between conveyors. If, for example, conveyor A handles 450 TPH of stone at a 330 FPM belt speed, then conveyor B will handle 450 TPH at a 165 FPM belt speed, as long as the conveyor width is adequate.

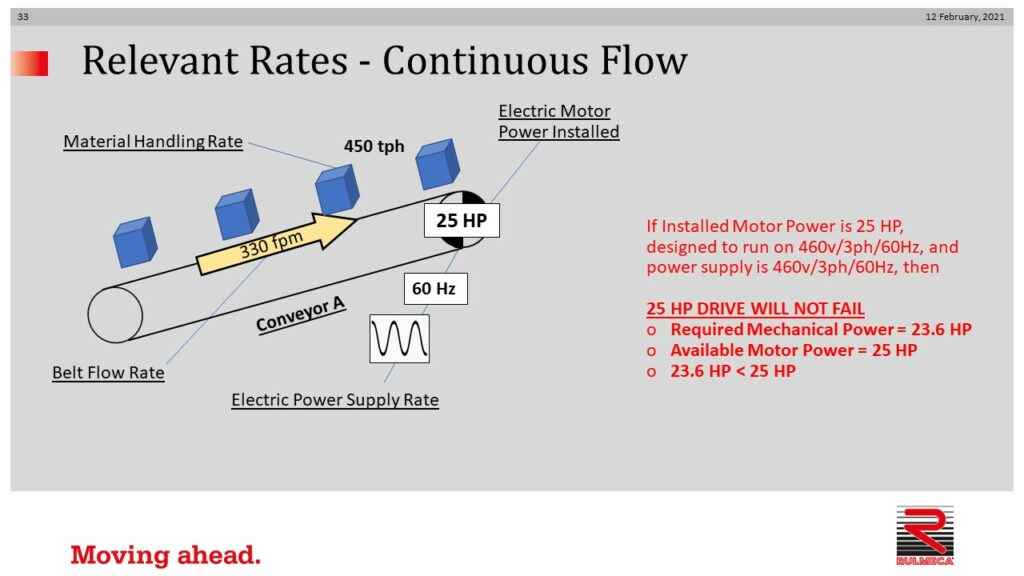

Analyze conveyor A as follows:

• Material Handling Rate = 450 TPH

• Conveyor Belt Speed = V = 330 FPM

• Power Supply = 460v/3ph/60Hz

• Motor is optimized to run on 460v/3ph/60Hz

The CEMA Conveyor Design Manual shows that required belt pull, Te, may be calculated using the equation below.

Te = LKt (Kx + KyWb + 0.015Wb) + Wm(LKy + H) + Tp + Tam + Tac

Required Power = Te x V

Required power to drive conveyor A = 23.6 HP.

A conveyor drive consists of an electric motor, gear reducer, and pulley. If the operator installs a 25 HP drive system, designed to run on a 460v/3ph/60Hz power supply, and the power supply is 460v/3ph/60Hz, the drive will not fail.

Required mechanical power = 23.6 HP

Installed power = 25 HP

Available power = 25 HP

23.6 HP is less than 25 HP

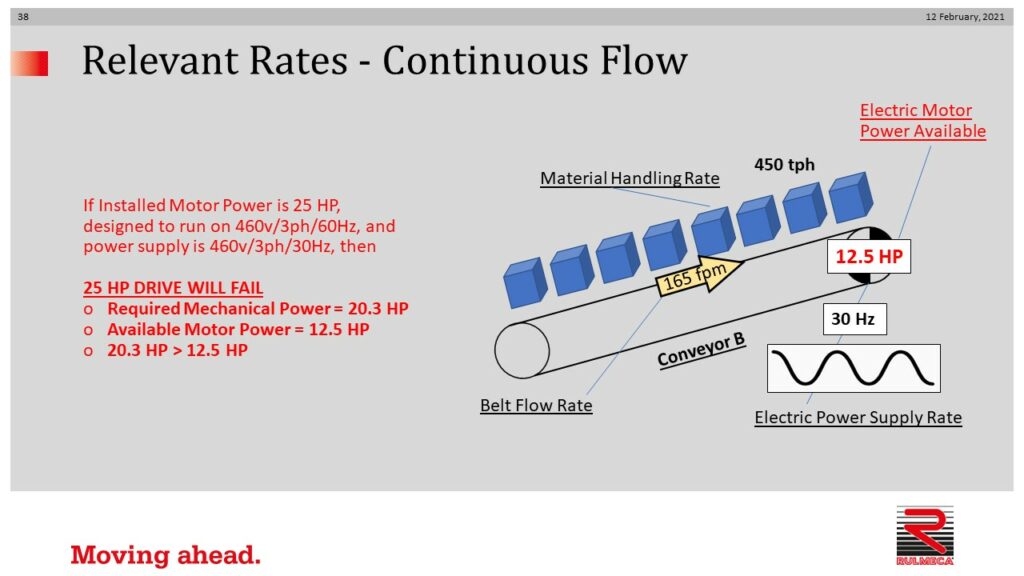

Analyze conveyor B powers as follows:

• Material Handling Rate = 450 TPH

• Conveyor Belt Speed = V = 165 FPM

• Power Supply = 460v/3ph/60Hz

• Motor is optimized to run on 460v/3ph/60Hz

If the operator uses the installed 25 HP drive system and the changes the supply frequency to 460v/3ph/30Hz to decrease belt speed to 165 FPM, then the drive will fail.

Required mechanical power = 20.3 HP

Installed power = 25 HP

Available power = 12.5 HP

20.3 HP is greater than 12.5 HP

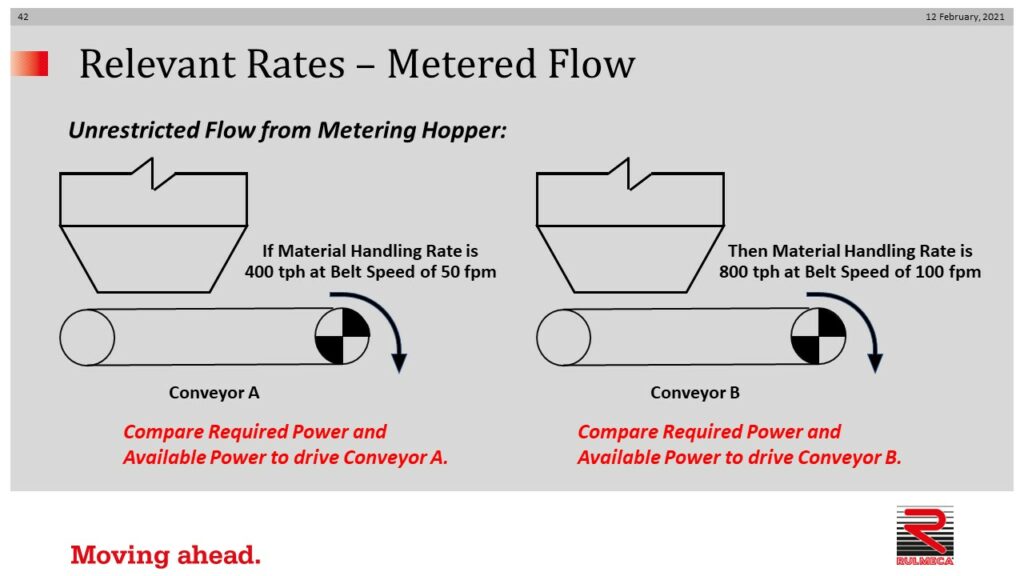

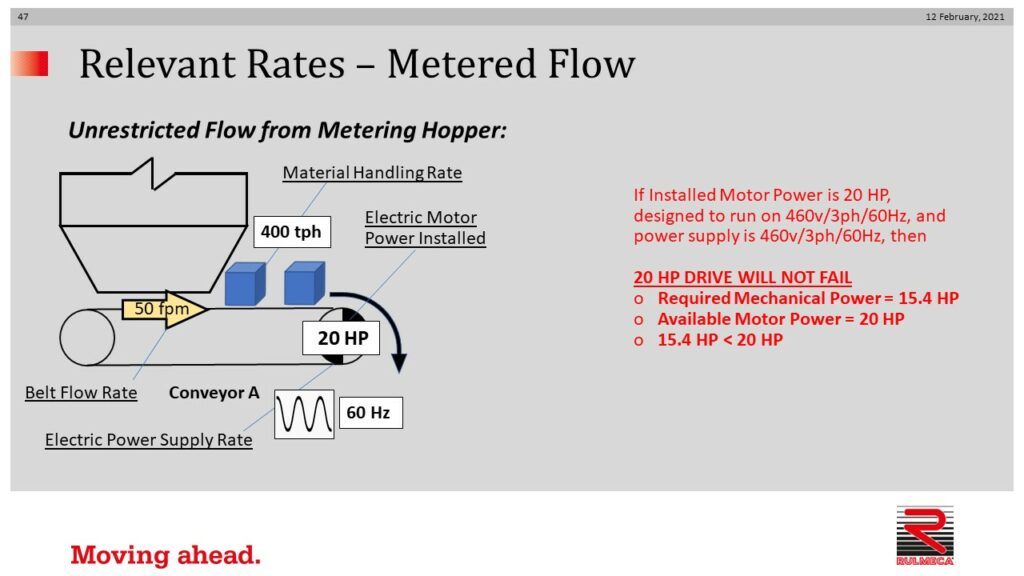

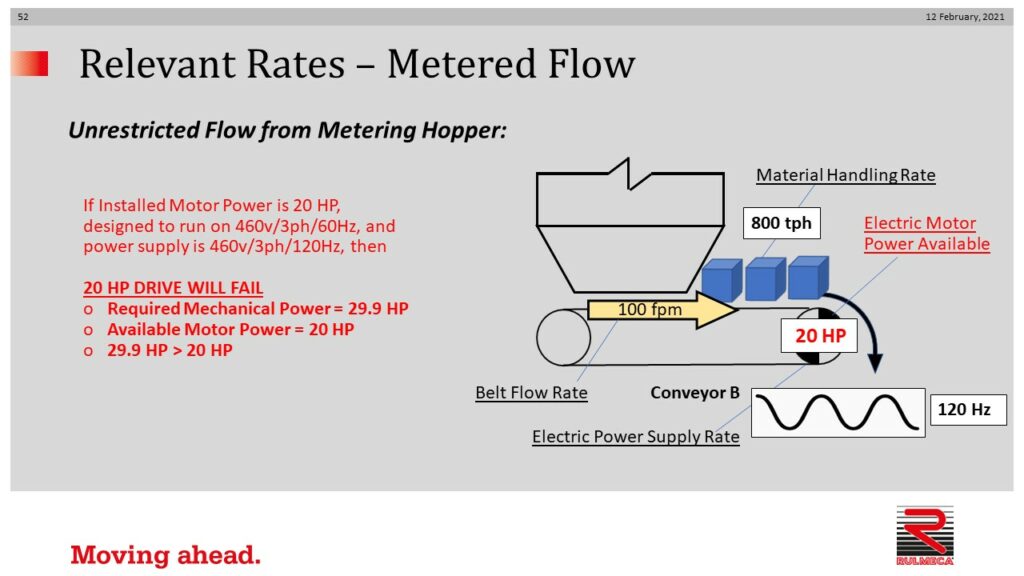

Two metered flow applications show the challenge of attempting to significantly increase belt speed with a VFD. In metered flow, material handling rate is linearly proportional to belt speed, as long as conveyor belt is sized appropriately. If conveyor A handles 400 TPH at a belt speed of 50 FPM, then conveyor B will handle 800 TPH at a belt speed of 100 FPM.

Analyze conveyor A powers as follows:

• Material Handling Rate = 400 TPH

• Conveyor Belt Speed = V = 50 FPM

• Power Supply = 460v/3ph/60Hz

• Motor is optimized to run on 460v/3ph/60Hz

Required power to drive conveyor A = 15.4 HP. If the operator installs a 20 HP drive system, designed to run on a 460v/3ph/60Hz power supply, and the power supply is 460v/3ph/60Hz, the drive will not fail.

Required mechanical power = 15.4 HP

Installed power = 20 HP

Available power = 20 HP

15.4 HP is less than 20 HP

Analyze conveyor B powers as follows:

• Material Handling Rate = 800 TPH

• Conveyor Belt Speed = V = 100 FPM

• Power Supply = 460v/3ph/120Hz

• Motor is optimized to run on 460v/3ph/60Hz

Required power to drive conveyor A = 29.9 HP.

Installed power = 20 HP

Available power = 20 HP

29.9 HP is greater than 20 HP

The drive system will fail. It is impossible to drive the motor at 120 Hz.