We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

HOW TO IDENTIFY TYPES OF MOTOR DAMAGE (PART 6 OF 6)

This video explains how to identify types of motor damage and provides an introduction to the company’s six-part tutorial on how to troubleshoot Rulmeca Motorized Pulleys. . Use this video in conjunction with our growing library of tutorials on how to design and maintain bulk handling belt conveyors.

We will conclude this six-part video tutorial on motor troubleshooting with some examples of the most common causes of motor damage. These are motor overload, over voltage, voltage surge, single phasing, and phase imbalance.

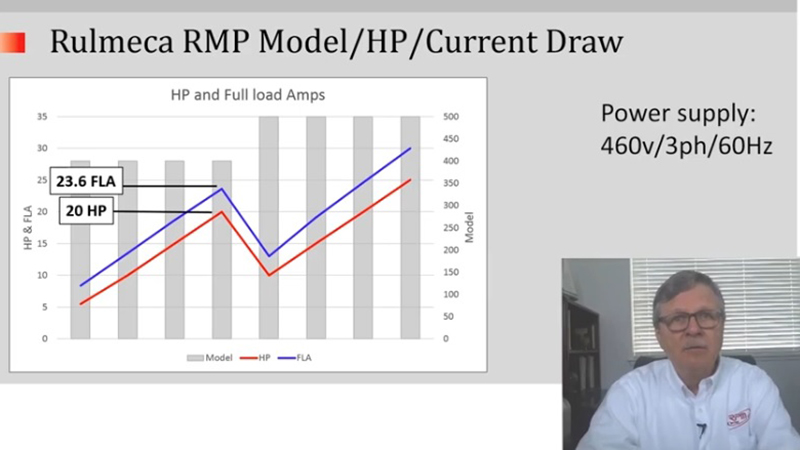

Remember the example presented previously. We reviewed an application in which a 20 horsepower (HP) Motorized Pulley was driving a conveyor at full load. The 20 HP motor, working at full load, draws 23.6 amps.

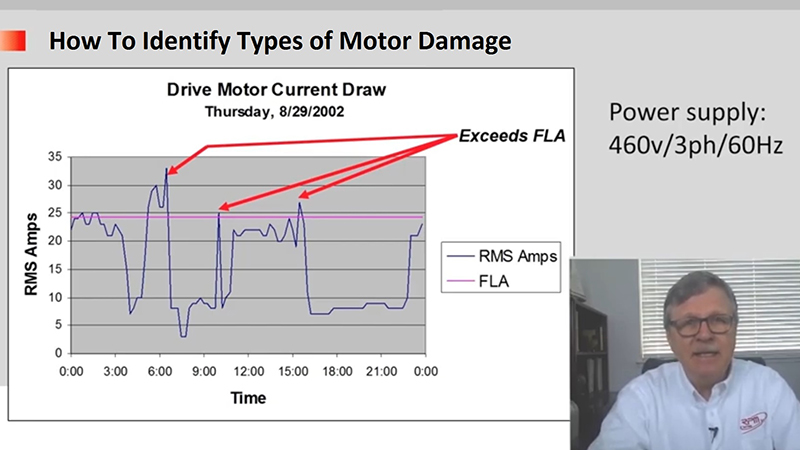

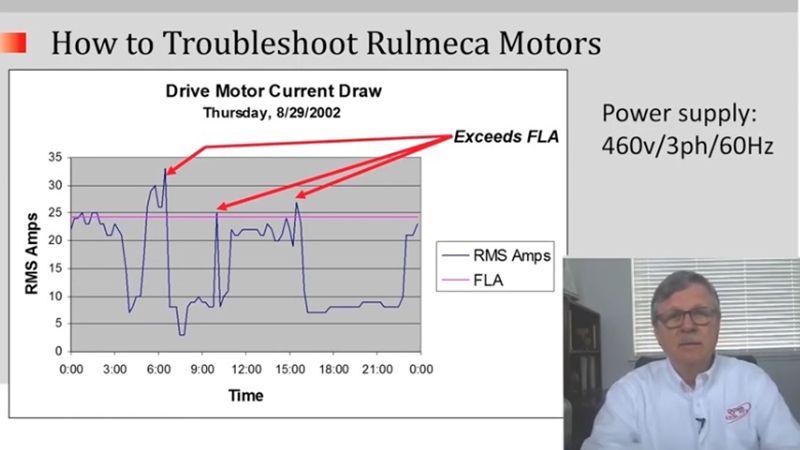

This is an actual example of a conveyor being driven by a 20 HP Motorized Pulley over a 24-hour period a few years ago. Notice that it exceeded full load amps several times in that 24-hour period.

Remember the graph shown in a previous video displaying an example of a 20 HP motor which will draw 23.6 full load amps (FLA). If that motor is required to provide more than 20 HP, it will draw more than 23.6 amps, more like 30 or 35 amps.

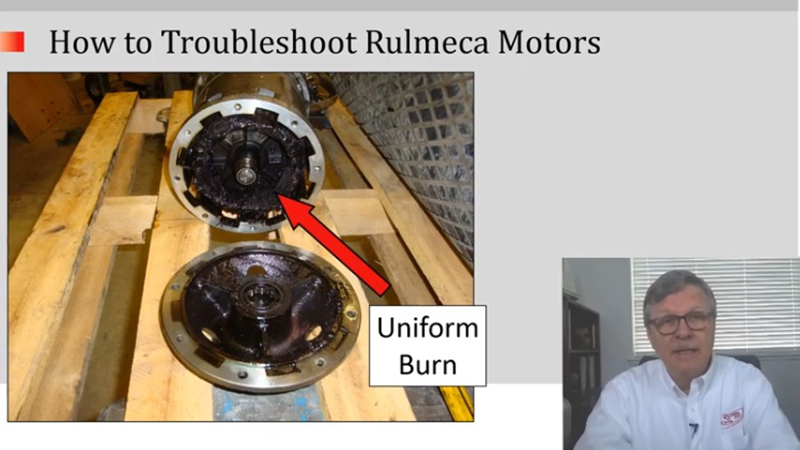

This is what a motor it looks like when it is subjected to an overload condition. Notice that the stator is uniformly burned. Two essential questions are:

- why was the 20 HP motor installed when 25 HP were required?

- why was the 20 HP motor allowed repeatedly to exceed full load amps?

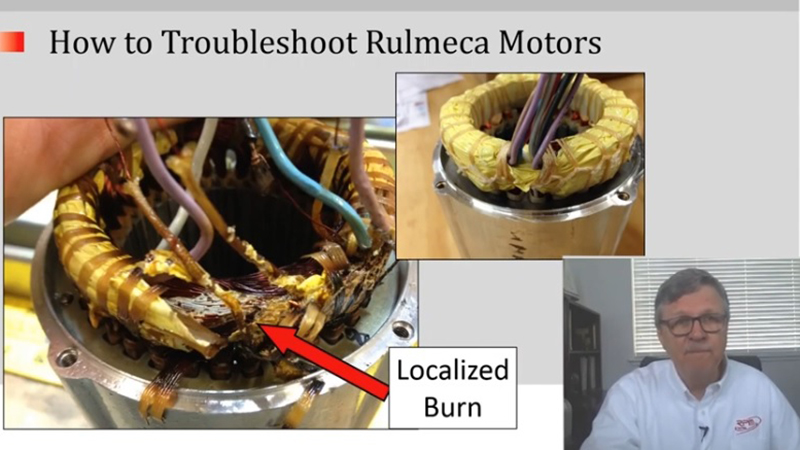

In this example we see a localized burn, which is typical of a voltage surge. A voltage surge can occur from a lightning strike or from a resonance-induced voltage spike. A resonance-induced voltage spike will occur when an unfiltered VFD is located too far from a motor. Motor damage from a lightning strike or a resonance-induced voltage surge will manifest itself as a very small pinprick of damage on the stator winding.

This photo was taken after a 230-volt motor was put into service on a 460-volt supply. Still it’s a localized burn, but it’s not a pinprick. This is another example of over-voltage motor damage.

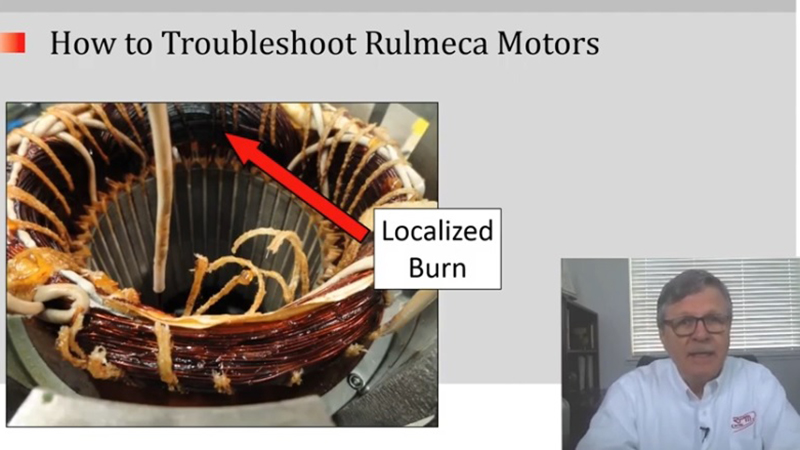

Finally, this is a localized burn caused by a phase imbalance or “single-phasing”. Notice that one of the phases at the top of the screen (at the arrowhead) is burned. However, the other two phases still have a bright copper (undamaged) color.

We hope these examples of motor damage are helpful. In this tutorial, we covered how a Rulmeca motor works to drive a conveyor. We reviewed the relationship between current draw and required power, which is very important. We also covered how to protect motors, how to check motors, and what are some of the common causes of motor damage.

We hope you enjoyed this tutorial. For more informative tutorials please subscribe to our YouTube channel. Thank you very much.