We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

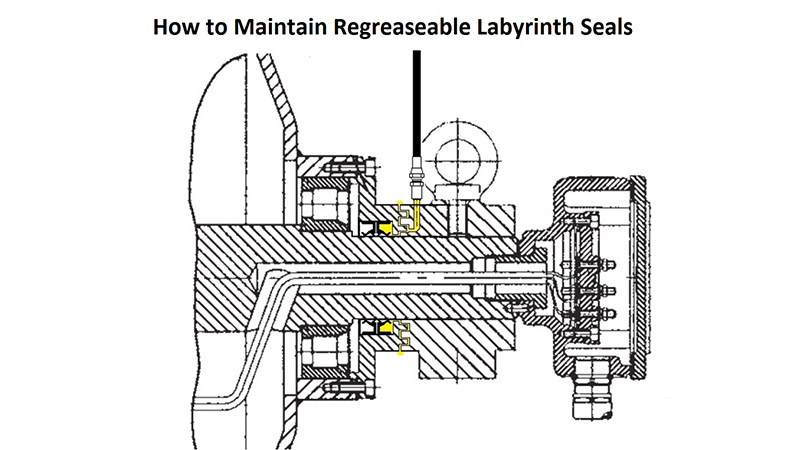

HOW TO MAINTAIN REGREASEABLE LABYRINTH SEALS

This video explains how to maintain optional regreaseable labyrinth seals in Rulmeca Motorized Pulleys. Use this video in conjunction with our growing library of tutorials on how to design and maintain bulk handling belt conveyors.

In this short video, you will learn how Rulmeca regreasable seals protect standard Motorized Pulley shaft seals, why it is necessary to purge them and how purging should be done.

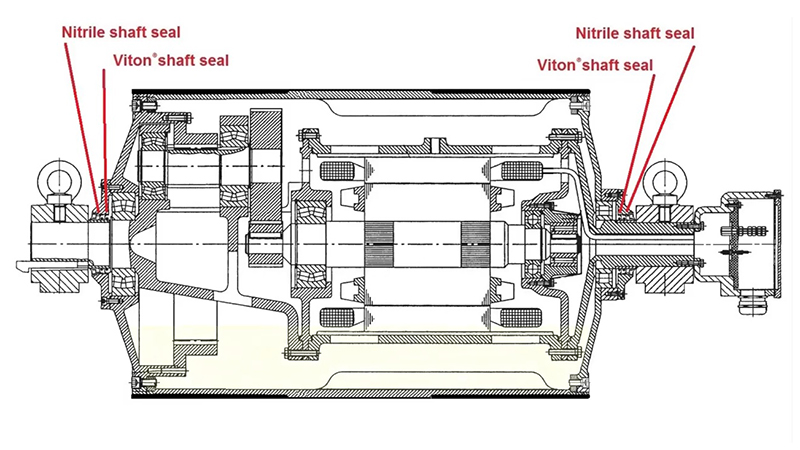

All Rulmeca Motorized Pulleys are hermetically sealed with spring-loaded Viton and nitrile shaft seals. They are designed to contain oil within the Motorized Pulley during normal operating conditions and can withstand the internal pressure rise which occurs as the pulley motor temperature increases. Regreasable labyrinth seals are an excellent option to protect standard shaft seals from harsh operating environments such as salt mines, iron mines, and taconite transfer terminals.

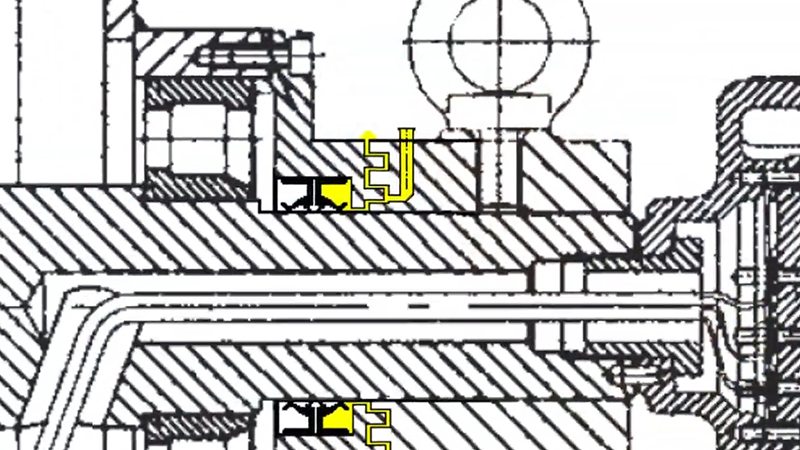

Each labyrinth seal provides a barrier of grease to prevent abrasive grit and corrosive fluid from attacking the shaft seals. In abrasive and corrosive operating conditions, labyrinth seals should be either continuously or periodically purged with grease to flush abrasive grit outward and away from the shaft seals.

A properly purged labyrinth seal will always display a bead of grease at the labyrinth gap as shown here.

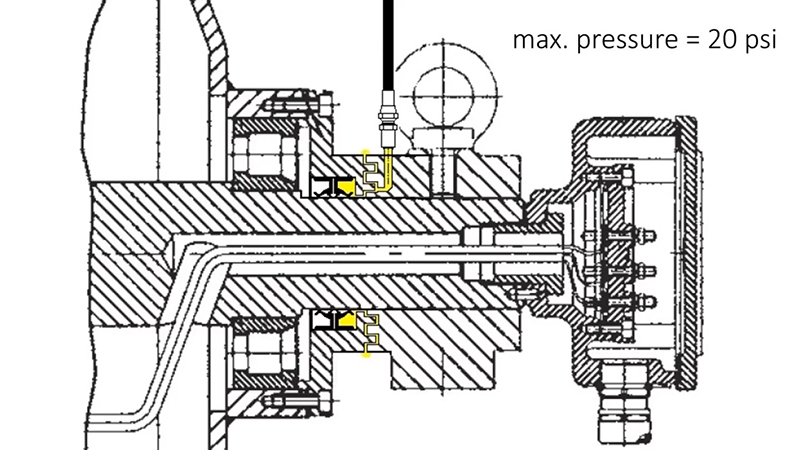

Manual grease purging with handguns is acceptable, provided the application pressure is limited to 20 PSI. Some handguns can apply grease at 10,000 PSI. This will cause grease to blow past the shaft seals and cause them to malfunction.

Automatic greasing systems are ideal when the re-grease frequency is high.

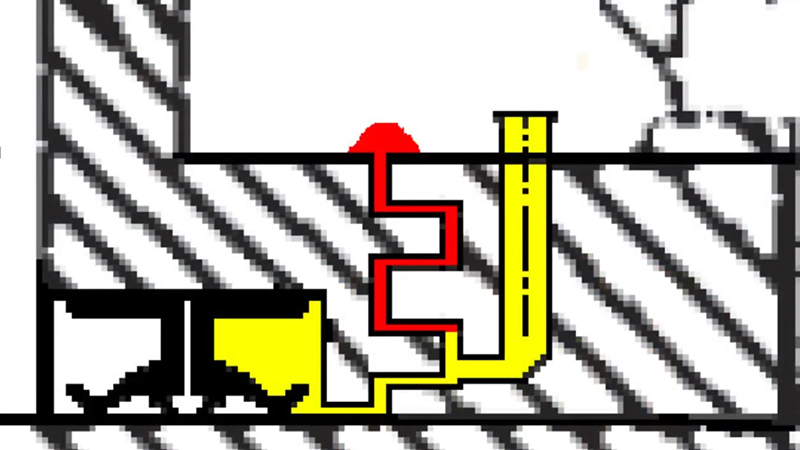

They can consist of individual grease canisters located near each shaft seal

or grease manifolds, which supply grease to multiple labyrinths as shown here.

Failing to perform proper labyrinth seal maintenance could shorten service life because it will allow grit-packed grease to impinge upon the shaft seals and shorten their life. We hope you found this short tutorial useful. For more tips on conveyor drive design and maintenance, go to RULMECACORP.COM or subscribe to our YouTube channel. Thank you very much.