We supply Motorized Pulley belt conveyor drives, serving equipment manufacturers directly and end users through a network of independent distributors & local service providers throughout the United States and Latin America.

HOW TO SOLVE CONVEYOR DRIVE RELIABILITY PROBLEMS

Welcome to our first video in this “Work from Home” videos series addressing various topics with conveyor drive problems. Today’s topic is reliability, and it’s March 31st. The video was sponsored by Rulmeca Corporation and I’m your host, Mike Gawinski. We’re a major supplier of Motorized Pulleys for the U.S. materials handling market and we’re headquartered in Wilmington, North Carolina. We’re part of the International Rulmeca Group, a major supplier of rollers, Motorized Pulleys, pulleys, and components for the global materials handling market. And we’re headquartered in Bergamo, Italy, with affiliates in 24 countries around the world.

Effective March 30th of this year, we were designated as “essential” during the COVID-19 response. So, we have continued production and repair of Motorized Pulleys in our Wilmington facility. However, all of our administration and sales staff are working from home, as I am today. This video is prepared for anyone working from home who is interested in belt conveyor operations and design.

To obtain help with conveyor belt power calculations and solve conveyor drive reliability problems, we suggest you do the following:

- Identify the conveyor drive problem

- Request technical assistance

- Consider potential solutions

- Obtain and consider a commercial offer

To obtain help with conveyor belt power calculations and solve conveyor drive reliability problems, we suggest you do the following:

- Identify the conveyor drive problem

- Request technical assistance

- Consider potential solutions

- Obtain and consider a commercial offer

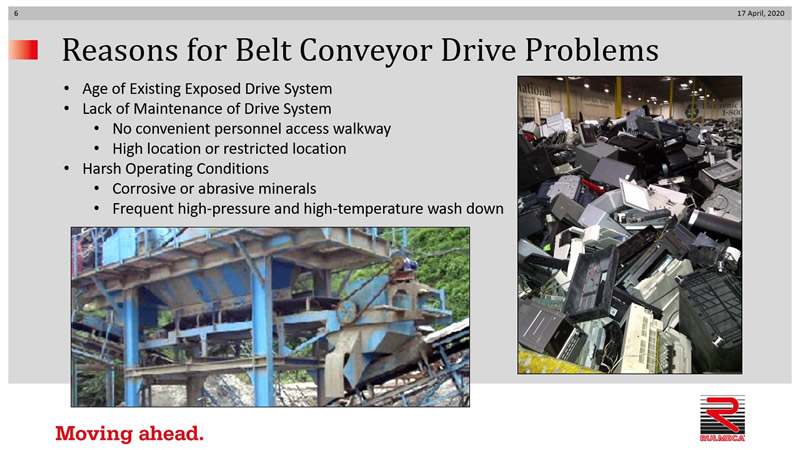

What are the reasons for belt conveyor drive reliability problems? They could be any one of a number of things or a combination, of the following:

- Age of an existing exposed drive system

- Lack of maintenance of a drive system

- no convenient personnel access

- the location may be high or restricted

- Harsh operating conditions

- corrosive or abrasive minerals

- frequent high-pressure and high-temperature wash down.

These two examples are in bulk handling and unit handling. The bulk handling application is an ancient picture (the chain of sprocket should be guarded with expanded metal), but the point is there’s no personnel access available to maintain that drive system. This drive would be problem-prone because it wouldn’t get maintained. The unit handling example might not seem challenging because recycling computers seems to be fairly straightforward. However, the presence of high-tensile material, such as video tapes or audio tapes in the recycling facility, makes exposed drive systems particularly prone to damage.

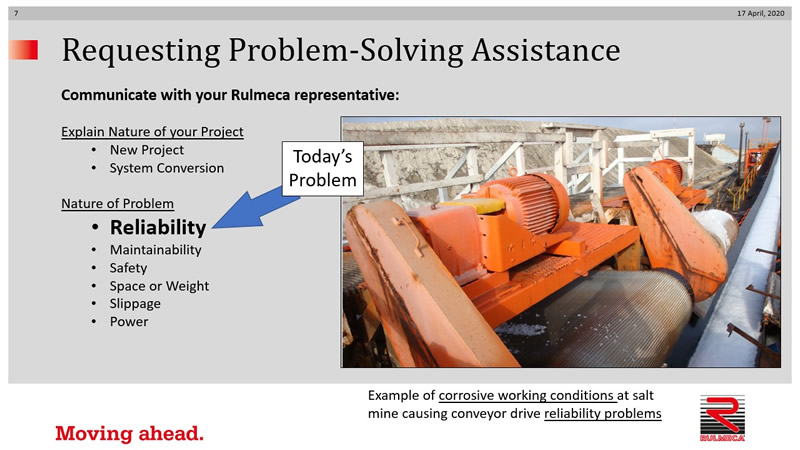

We encourage you to reach out to your Rulmeca representative, one of our authorized local distributors, one of our sales representatives, or one of our own salespeople. Nowadays, many of us are working from our homes. We’re not making sales calls, inspecting conveyors, visiting with customers. Many conveyor operators and engineers are also working from home as much as possible.

We need to know:

- Nature of your project (i.e. is it a new project or is it a system conversion)

- Nature of the problem (e.g. reliability)

Today we will explore an example of a very corrosive working condition at a salt mine which is causing conveyor drive reliability problems.

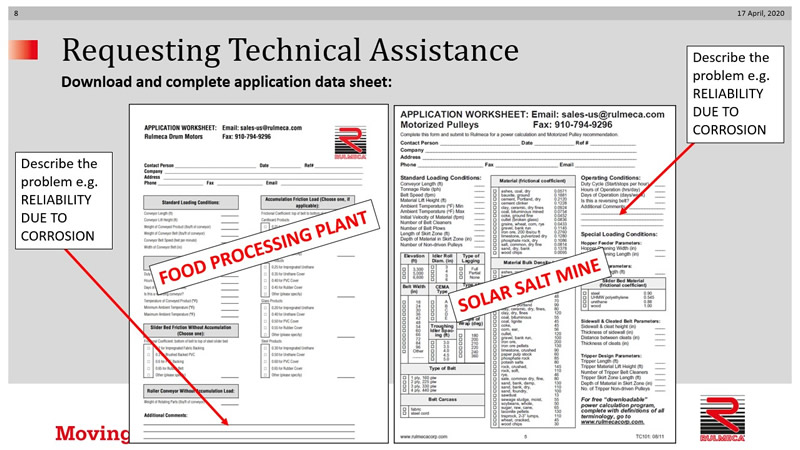

How do you get assistance? First, send us an application data sheet (downloadable from our website or available online).

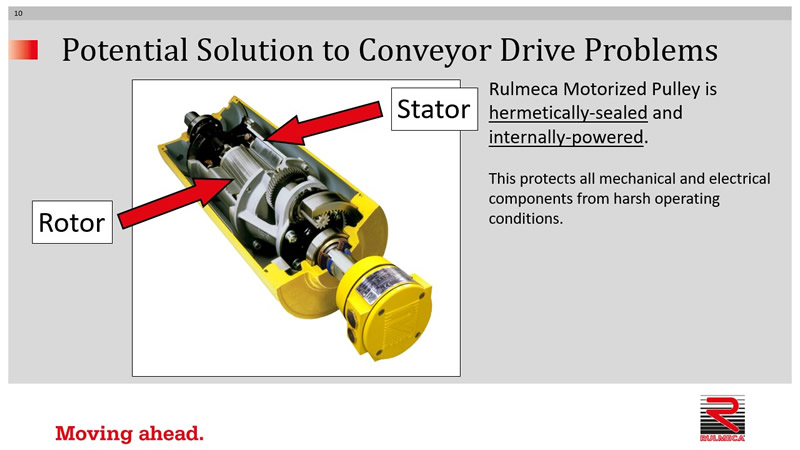

Here’s a potential solution to an exposed drive system reliability problem due to corrosion. It is the Rulmeca Motorized Pulley, which is hermetically sealed and internally powered. This design protects all mechanical and electrical components from harsh operating conditions.

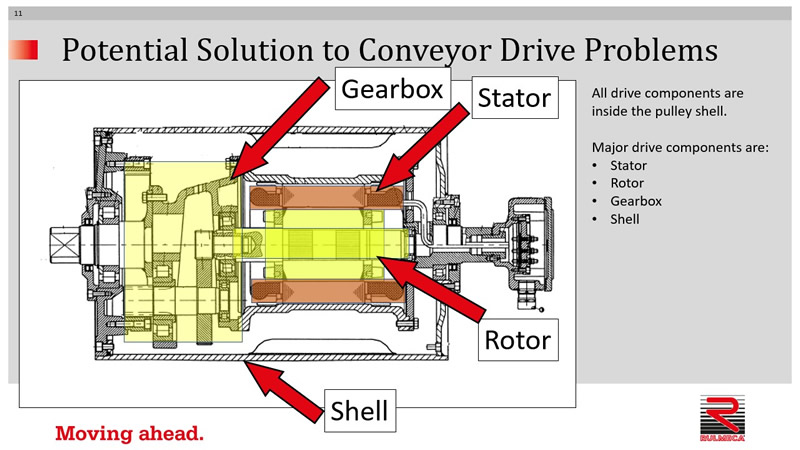

As you can see, all drive components are inside the pulley shell. The stator, rotor, gearbox and shell all work together, protecting the drivetrain (the parts most susceptible to corrosion damage) within a hermetically sealed enclosure.

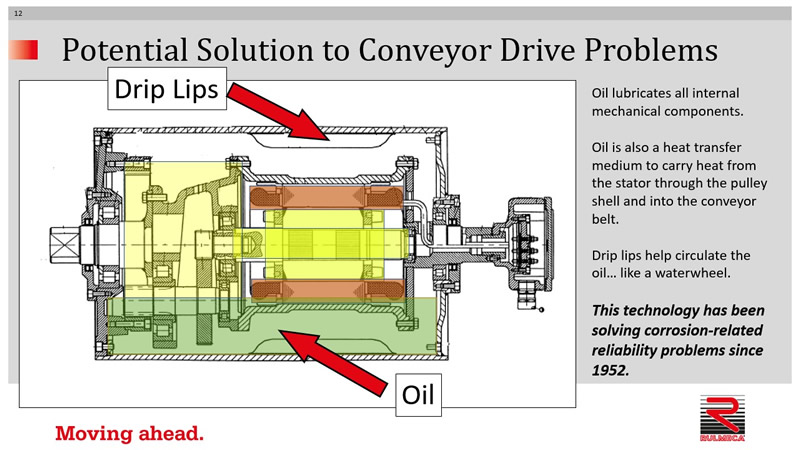

As you can see, the pulley is filled with oil. The oil lubricates all internal mechanical components, including motor rotor bearings, which never get lubricated in the field. The oil also serves as a heat transfer medium to carry heat away from the stator through the pulley shell and into the conveyor belt. This technology has been around since the early 1950s.

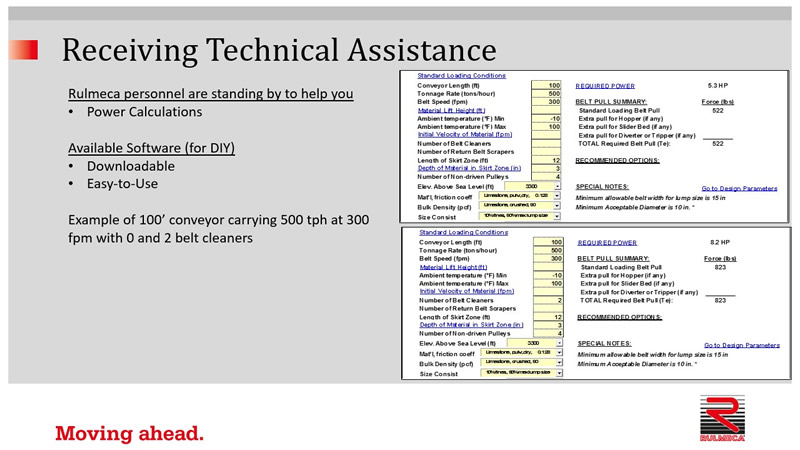

Our response to drive-related problems often includes power calculations, as shown here. We perform these calculations regularly. The power calculation program is also downloadable from our website. This is an extract from our full sheet of parameters and recommendations. It shows that 5.3 HP is the required drive power for a 100 ft long conveyor carrying limestone at 500 tons per hour (TPH) at 300 feet per minute (FPM) with no belt cleaners. We re-ran the calculations with two belt cleaners and show that 8.2 HP is required.

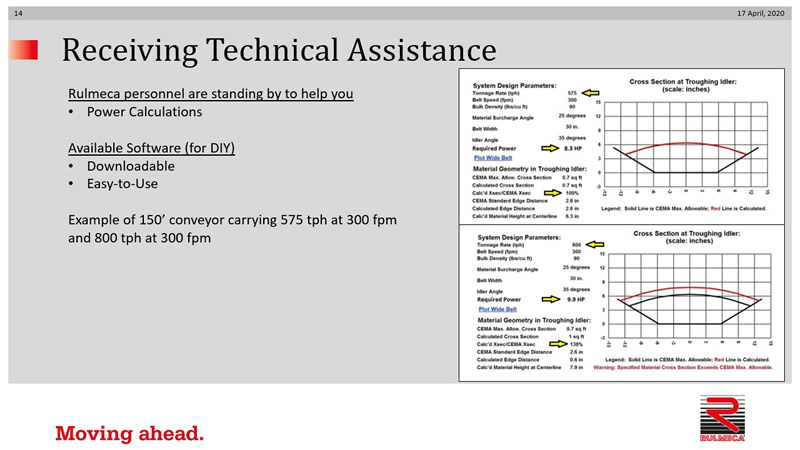

Here is another example of output from our technical review, which we do at no charge for anyone who has a problem. This shows two sets of parameters for a 150 foot long conveyor. One shows the cross section for a 30” wide belt carrying 575 TPH at 300 FPM. The other shows 800 TPH at 300 FPM on that belt.

This video addressed conveyor drive reliability, focusing on corrosion-related problems causing production interruptions. Other videos will address:

- Maintainability

- Safety

- Space and Weight Problems

- Belt Slippage and Bounce

- Inadequate Power

I draw to your attention our growing library of video tutorials, which you can find on our website and our YouTube channel, along with all of the webinar recordings and all of the Work from Home videos.

Thank you for your attention. If you have any questions related to conveyor drive technology, conveyor drive problems or conveyor belt power calculations, please don’t hesitate to contact us at sales-us@rulmeca.com.