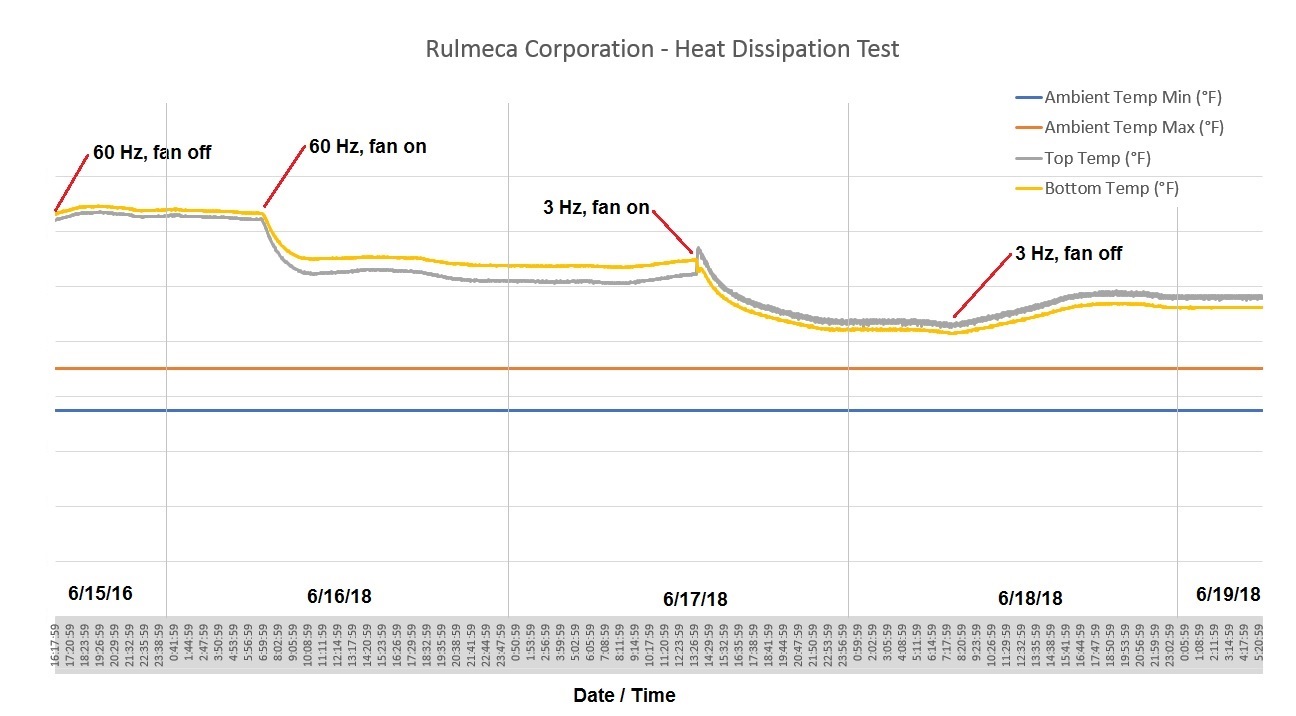

Rulmeca Corporation was recently challenged by the slow hopper feeder conveyor speed (2 fpm) of a major chemical producer’s process. So, they designed and alpha tested a unique pneumatic heat dissipation system to cool the external surface of the Motorized Pulley to maintain the internal motor operating temperature at its normal operating level.

Several days of continuous temperature monitoring, under a variety of frequency and heat dissipation conditions, proved that the model 400H can be adequately cooled by external means in spite of the slow belt speed. Note that, in normal steady-state conditions, Rulmeca Motorized Pulleys are cooled by using the conveyor belt as an infinite heat sink.

Several days of continuous temperature monitoring, under a variety of frequency and heat dissipation conditions, proved that the model 400H can be adequately cooled by external means in spite of the slow belt speed. Note that, in normal steady-state conditions, Rulmeca Motorized Pulleys are cooled by using the conveyor belt as an infinite heat sink.