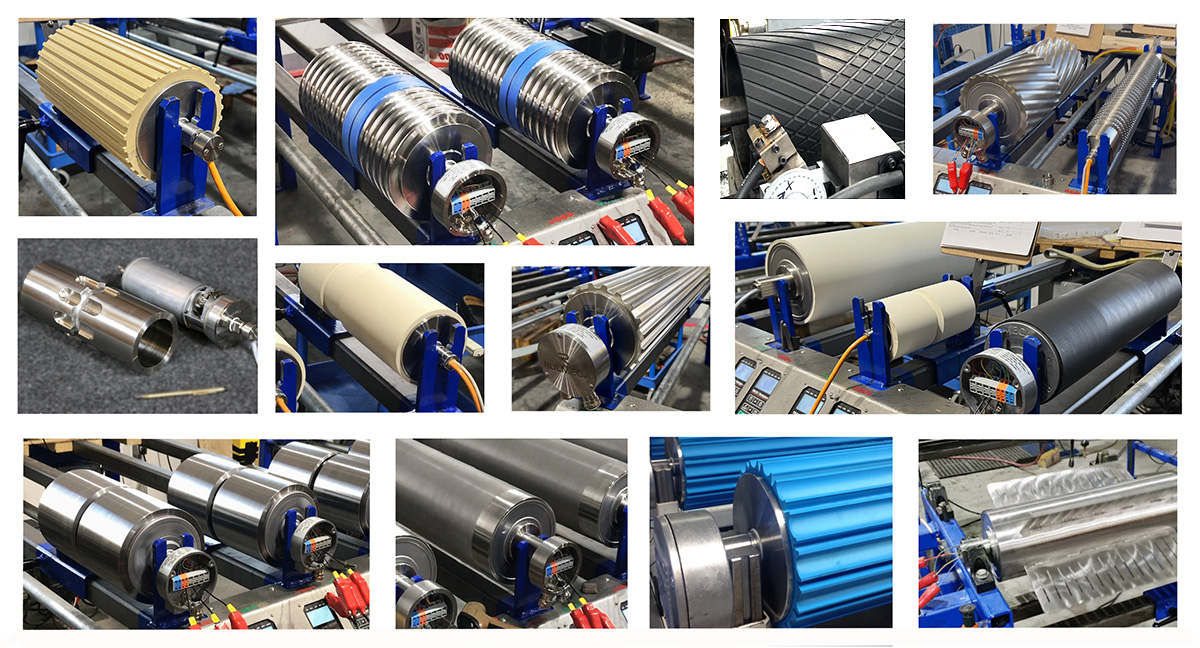

With all of the major “Horizon Project” equipment now installed and in production, the Rulmeca Corporation portfolio of Motorized Pulley shell configurations is expanding rapidly. Progressively bringing more of our shell production in-house, we have cut lagged shell production lead time in half, while maintaining our high quality standards. We now have hundreds of shell profiles, both lagged and unlagged, in five Motorized Pulley models in our growing product offering.

Our new autoclave and CNC rubber grinder/hot knife lathe have enabled our production staff to quickly respond to a growing list of customer requests for nitrile rubber lagging (in various colors) with and without grooves.

Our new autoclave and CNC rubber grinder/hot knife lathe have enabled our production staff to quickly respond to a growing list of customer requests for nitrile rubber lagging (in various colors) with and without grooves.

Continuing to work with outside suppliers, as necessary, we are responding to a rapidly growing list of requests for stainless steel shells with welded keys, sprockets, and paddles as well as thick-wall shells with transverse and longitudinal grooves.

Continuing to work with outside suppliers, as necessary, we are responding to a rapidly growing list of requests for stainless steel shells with welded keys, sprockets, and paddles as well as thick-wall shells with transverse and longitudinal grooves.