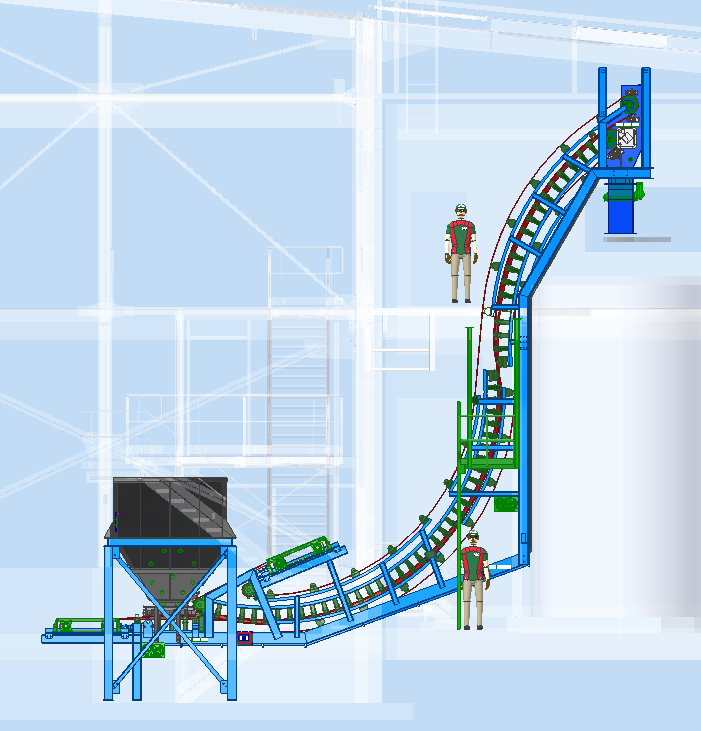

Dos Santos International installed two Rulmeca Motorized Pulleys in the Sandwich Belt high angle conveyor they supplied to SNF Coagulants for a plant expansion in St Avold, France. Celebrating its 25th year in business, DSI has installed Sandwich Belt high angle conveyors at mines, ports, tunneling projects, recycling facilities, and other bulk handling facilities throughout the world.

DSI chose two model 320H Rulmeca Motorized Pulleys, each with a 5.5 HP electric motor and 76 fpm nominal belt speed on a 380v/3ph/50Hz power supply, to drive the two Sandwich Belts. Providing the belt tension required to move the load from the discharge point, each RMP was outfitted with a counterclockwise mechanical backstop to prevent material dropping when the motor is de-energized. Rulmeca Motorized Pulleys are internally-powered, hermetically-sealed, oil-filled belt conveyor drives. Each Motorized Pulley uses a three phase, squirrel cage, electric induction motor to rotate the pulley shell through a two or three stage gear reducer and uses multiple double lip shaft seals to contain the oil.

Key factors in the selection of Rulmeca Motorized Pulleys were:

• Compact size

• Light weight

• High reliability

• Personnel safety

• Ease of maintenance

Since their introduction more than 70 years ago, Rulmeca Motorized Pulleys have been driving conveyors in mining, ports, utilities, tunneling projects, and other bulk handling facilities as well as food processing, package handling, and unit processing throughout the world.

The DSI Sandwich Belt conveyor for SNF Saint Avold transfers magnetite at a rate up to 30 tph, drawing the material from a hopper, elevating it 30 feet, and discharging it into one of two processing tanks. The direction of the material is achieved by a bifurcated chute, also designed and supplied by DSI. The DSI Sandwich Belt high angle conveyor uses two conveyor belts, face-to-face, to gently but firmly contain the product being carried, hence making steep incline and even vertical-lift runs easily achievable. The DSI Snake hugs the bulk materials by the use of radial pressure which is due to the belt tension and the alternating curving profile geometry. Materials are conveyed along the convex curves in a “snaking” profile as they are elevated to the highest of angles.

The DSI sandwich belt conveyor offers the following advantages when compared with other vertical lift technology (e.g. bucket elevators):

• Unlimited conveying capacity

• Suitable for rugged mine applications

• Gentle on sensitive and friable material

• High availability and low operating and maintenance cost

• Smooth belts allow belt cleaning by scrapers and plows

Note also the Sandwich Belt facilitates intermediate material discharge by belt plows, as appropriate, before and/or beyond the sandwiched part of the snaking profile. Conventional conveyor hardware ensures economy and fast delivery of replacement parts.

SNF chose the DSI Sandwich Belt high angle conveyor solution, along with DSI’s innovative approach to maintain a high level of R&D expenditure along with continual investment in improving and expanding its production sites. SNF now accounts for almost half of all global polyacrylamide production, which underscores the effectiveness of their innovation and investment policy.

SNF is a privately-held, specialty chemical company based in the Rhone-Alpes region of France, with a long-standing presence on every continent. With 21 production sites in Europe, Asia, Australia and America, and with a production capacity of 1,235,000 tons, SNF has the largest polyacrylamide production capacity in the world.

As a leader in manufacturing and processing water-soluble polymers (based on polyacrylamide), SNF has developed a range of more than 1,000 products that help preserve our natural resources, encourage recycling and improve efficiencies of industrial processes. Their polymers are used in all markets where water is present: drinking water production, wastewater treatment, sludge dewatering, oil and gas extraction, mining, agriculture and the manufacture of paper, textiles and cosmetic formulations.

For more information on DSI Sandwich Belt high angle conveyors, click here.

For more information on Rulmeca Motorized Pulleys, click here.